3D Printing Infill Patterns

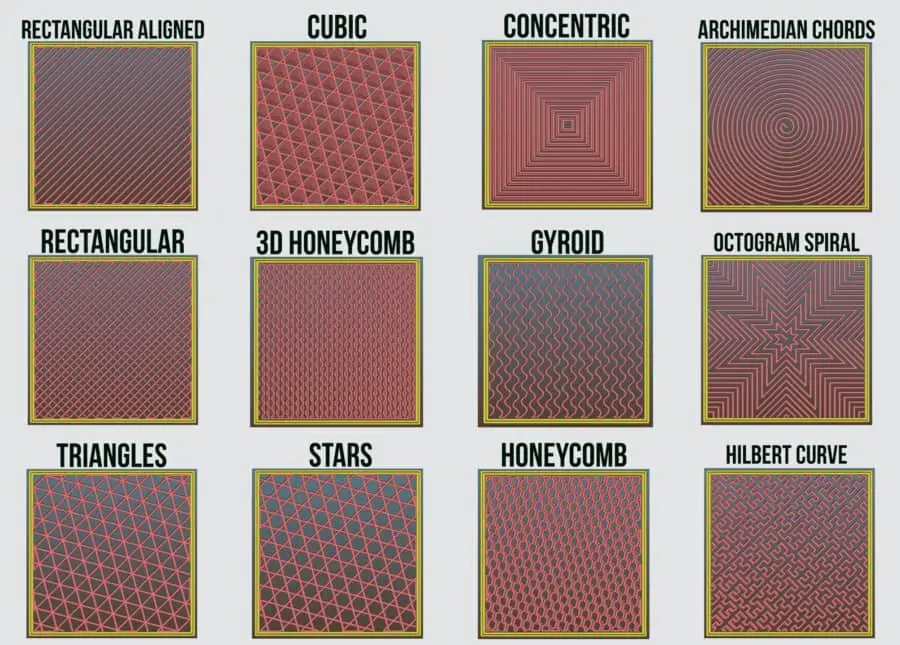

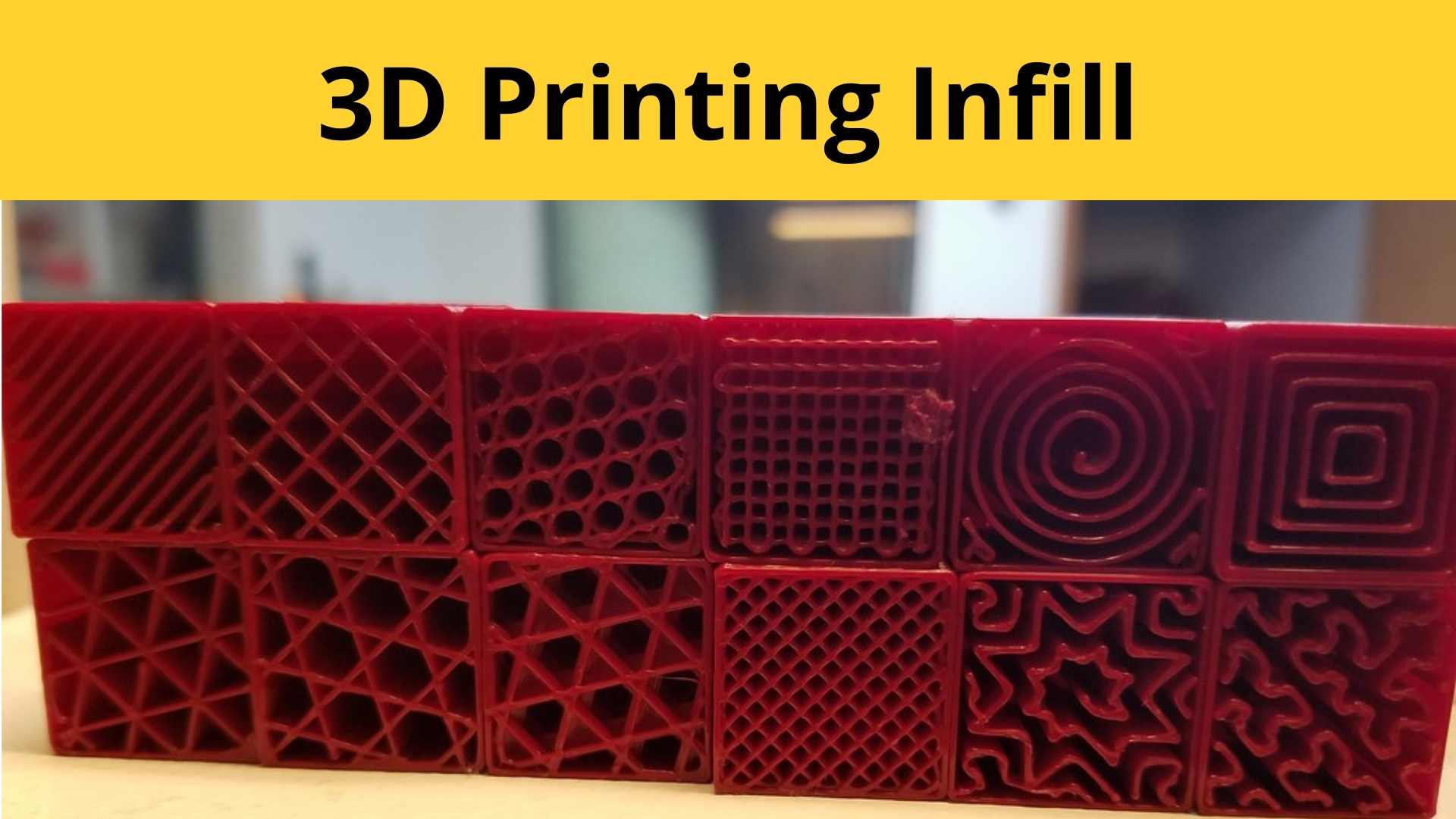

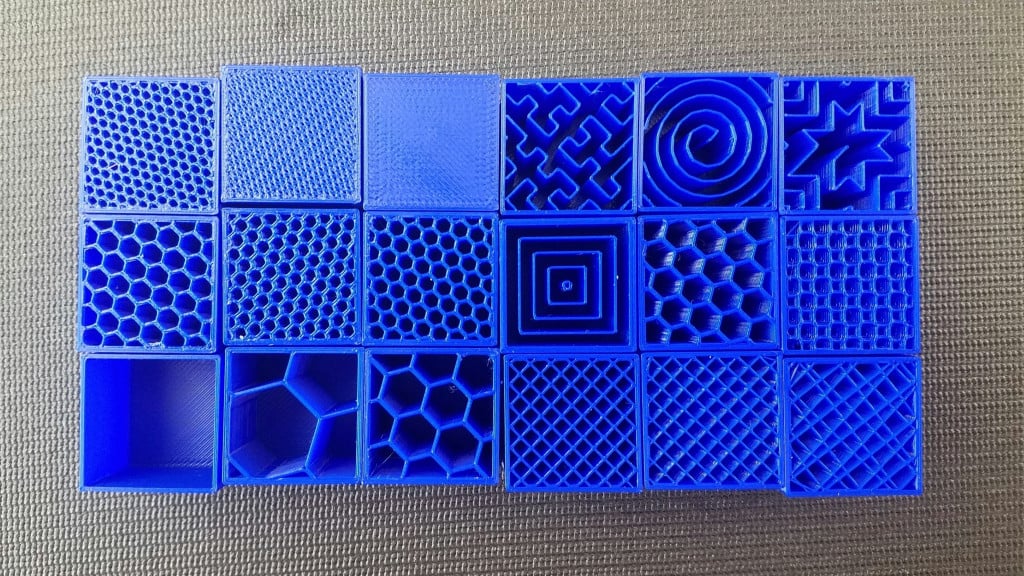

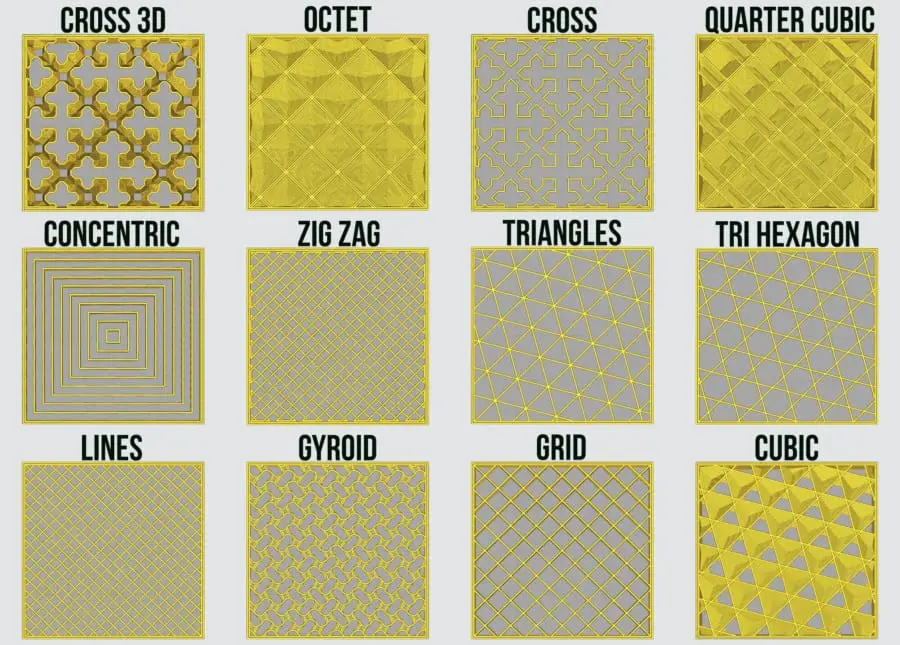

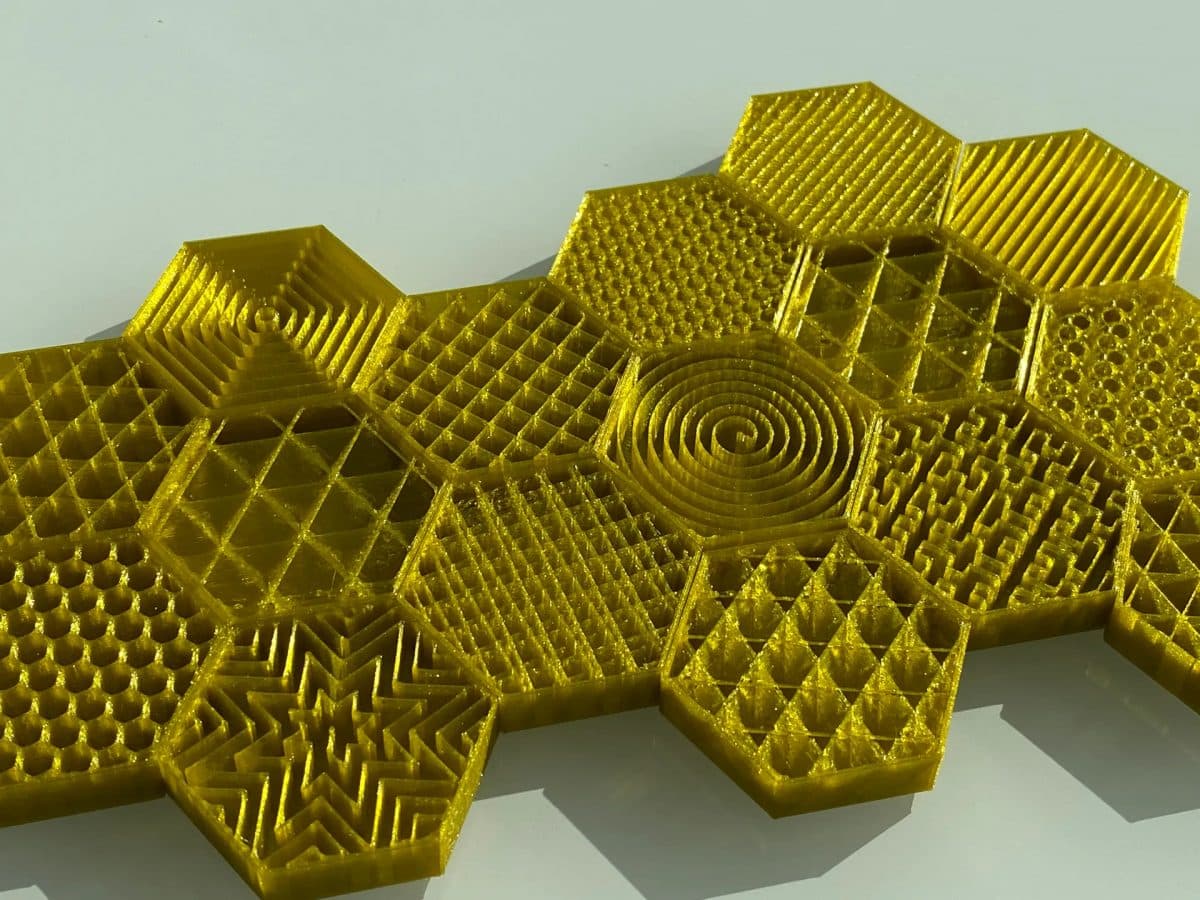

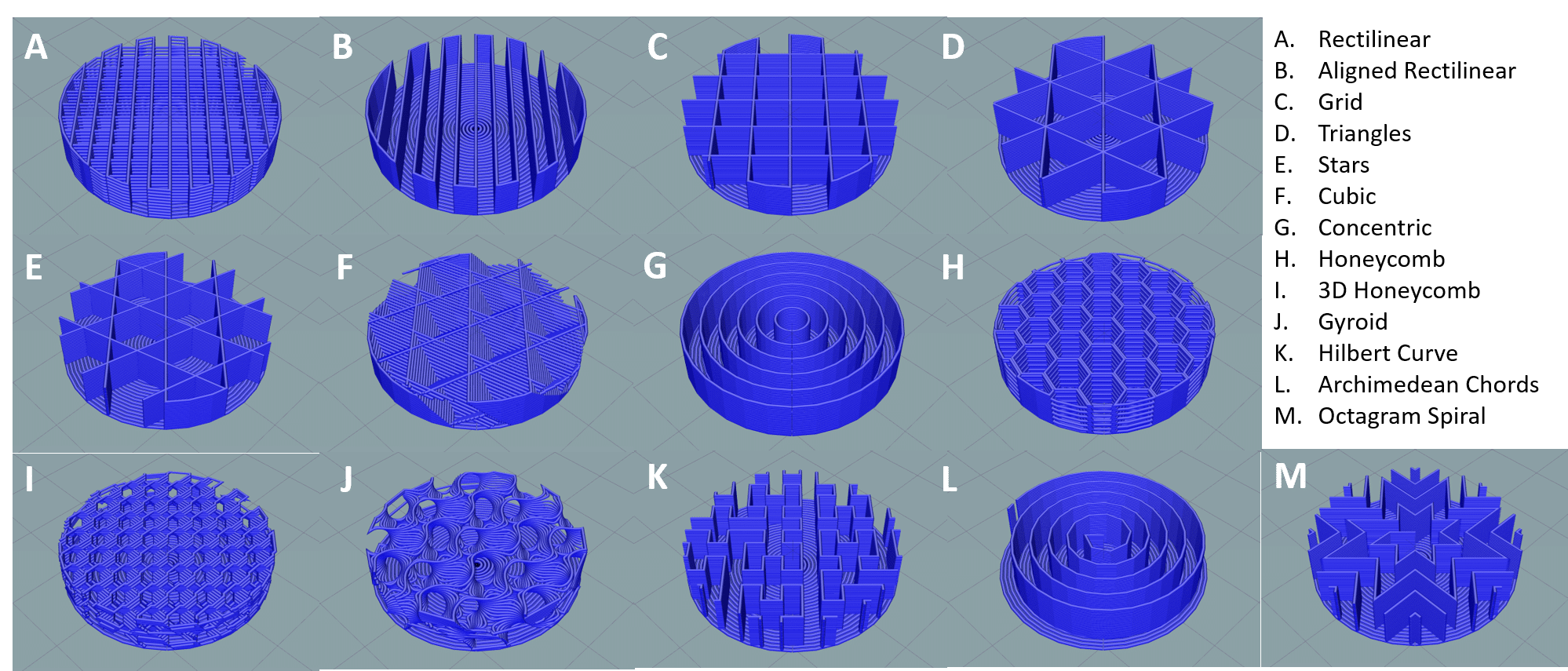

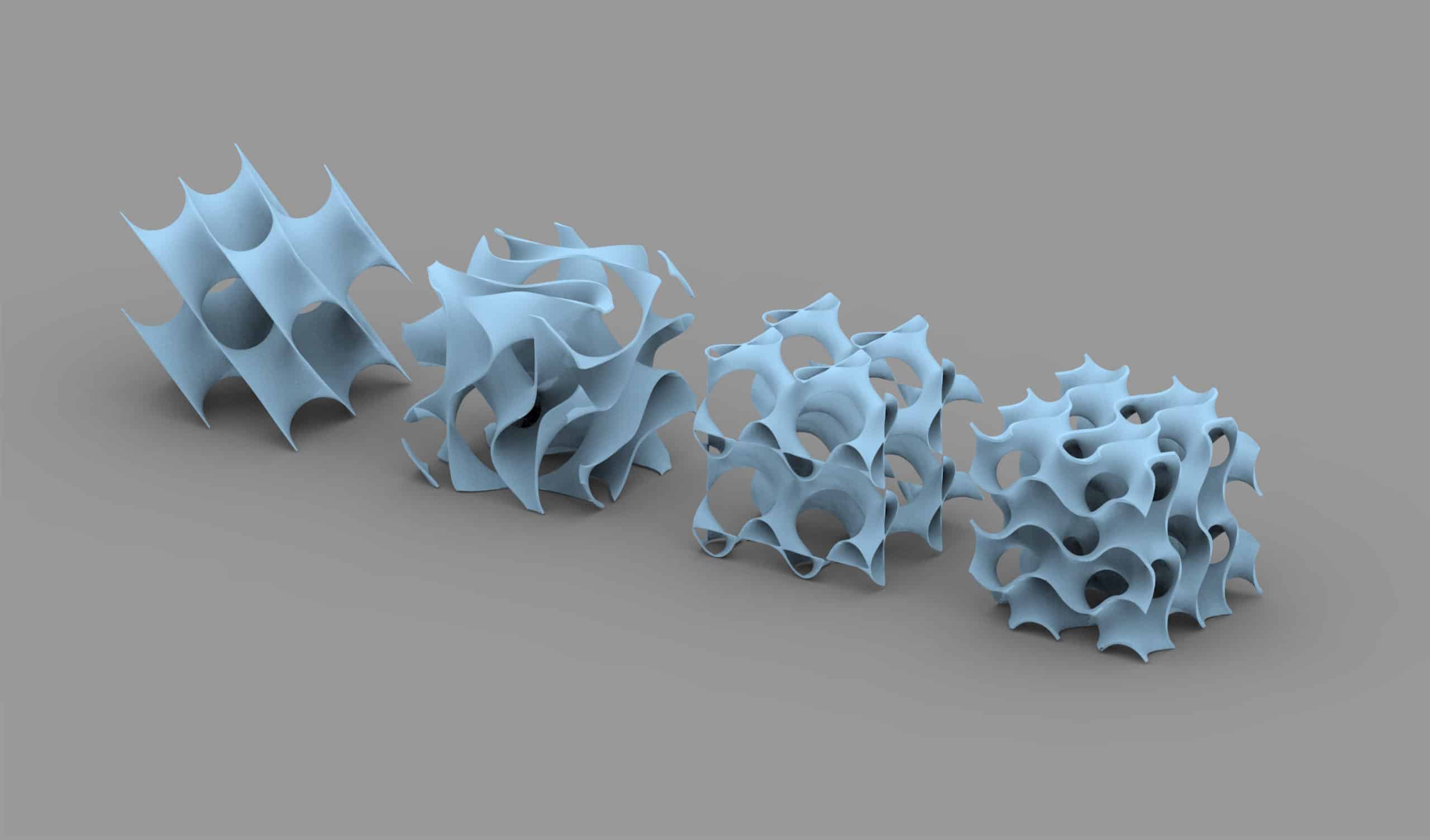

3D Printing Infill Patterns - This newly released infill is best for objects that don’t need great mechanical stability. In 3d printing, infill plays an important role in a part's strength, structure, and weight. The gyroid 3d printing infill pattern creates alternating wavy lines or curves. In 3d printing, infill plays an important role in a part's strength, structure, and weight. Besides the actual printing process, infill will affect the strength or feel of the final product. You can rotate, zoom in, and scrutinize every angle of the model to ensure. Unfortunately, picking the right infill pattern for your model can take practice and a bit of paying attention to the geometry of the model and the infill pattern. Web infill is the inner structure of a 3d printed object. It is suited to visual prints like. By alejandro benítez de la riva, jackson o'connell. 3d printed model with grid infill pattern. Web the strongest infill patterns. Like the grid and triangular infill types, it will cross over itself to create a hexagonal pattern interspersed with triangles. There is no strongest 3d printing infill pattern, although gyroid and cubic both come close. Web infill provides the 3d print with internal support as the printer builds. 25% more) compared to other infills, and print time that can take up to twice the time of previously described options. A cubic infill pattern is more commonly available in most slicers. Creates multiple cross shapes as infill. There is no strongest 3d printing infill pattern, although gyroid and cubic both come close. Web there's more than one option when. Again, this is one of the most common (and basic) types of top infill. Prototyping and simple 3d prints Infill serves as the internal support structure for 3d printed objects. It’s very quick to print this infill pattern, and they don’t require too much material either. 3d printed model with grid infill pattern. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. This infill pattern takes longer to print than the others. It is suited to visual prints like. However, the unique gyroid internal structure allows for almost isotropic mechanical properties. 25% more) compared to other infills, and print time. Web there's more than one option when it comes to selecting infill patters for your 3d prints. 7%, 20%, 50%, and 75%. Read on to learn more about it. The overall strength of the infill patterns depends on the direction of the force. Web in this comprehensive guide, we will explore the concept of infill in 3d printing, discuss the. Web understanding the kind of load your 3d parts will have to withstand is critical in picking the best infill pattern. The overall strength of the infill patterns depends on the direction of the force. Infill serves as the internal support structure for 3d printed objects. Web in this comprehensive guide, we will explore the concept of infill in 3d. Web 🤹♂️ choosing the right infill pattern for your 3d printing project isn't always easy! The main disadvantages are higher material consumption (approx. Slicers offer many infill pattern options, but not all of them yield strong 3d prints. Prototyping and simple 3d prints There is no strongest 3d printing infill pattern, although gyroid and cubic both come close. It’s very quick to print this infill pattern, and they don’t require too much material either. Web the lines infill pattern is something you can use for very basic needs. This pattern consists of only one line, with the lack of directional changes saving the printer time. Web infill patterns focused on strength are preferable if you’re 3d printing functional. Prototyping and simple 3d prints Read on to learn more about it. This pattern consists of only one line, with the lack of directional changes saving the printer time. Like the grid and triangular infill types, it will cross over itself to create a hexagonal pattern interspersed with triangles. Web the lines infill pattern is something you can use for. You can rotate, zoom in, and scrutinize every angle of the model to ensure. In 3d printing, infill plays an important role in a part's strength, structure, and weight. All seven types of top (bottom) infills printed with 80% flow to highlight the patterns. Web infill is the inner structure of a 3d printed object. Higher infill percentages result in. Sometimes you've got to juggle options like a pro. 7%, 20%, 50%, and 75%. This pattern consists of only one line, with the lack of directional changes saving the printer time. The pattern is also pretty straightforward, and nothing complicated going on with it. Sliced models of most common infill patterns designed to hang on a string near your 3d printer(s) 5h 35m. The major benefit of using the grid pattern is the reduction in print time. However, the unique gyroid internal structure allows for almost isotropic mechanical properties. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. It is suited to visual prints like. But what are the differences, and why should you use one over the. First and foremost, infill patterns determine the internal structure of a print, which directly affects its strength and stability. You can use the pattern for printing pieces that you will use for displays. The gyroid 3d printing infill pattern creates alternating wavy lines or curves. 25% more) compared to other infills, and print time that can take up to twice the time of previously described options. Web the lines infill pattern is something you can use for very basic needs. The cubic infill pattern is a strong 3d infill pattern that is made up of stacked cubes that.

3D Print Infill Patterns Explained The 3D Bros

Guide to 3D printing infill settings its pattern, percentage and

TESTING 3D printed INFILL PATTERNS for their STRENGTH YouTube

Infill Pattern Basics Simplify3D YouTube

3D Printing Infill The Basics Simply Explained All3DP

3D Print Infill Patterns Explained The 3D Bros

5 Strongest Infill Patterns Every 3D Print Slicer Should Have

Infill Pattern Options in Slic3r Infill Options for Bioprinting

3D Printer Infill Patterns The Basics YouTube

3D printing infill patterns and their benefits REALvision Pro

The Overall Strength Of The Infill Patterns Depends On The Direction Of The Force.

The Basics For Perfect Results.

Web Interactive Model Previews:

Prototyping And Simple 3D Prints

Related Post: