30 Bolt Torque Pattern

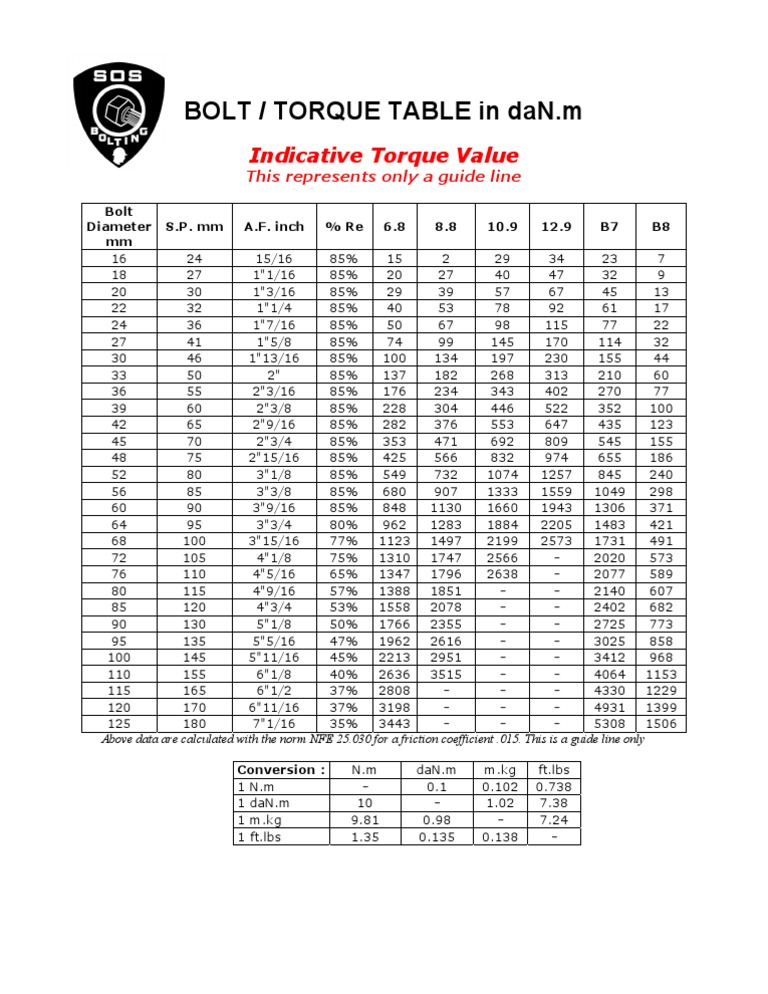

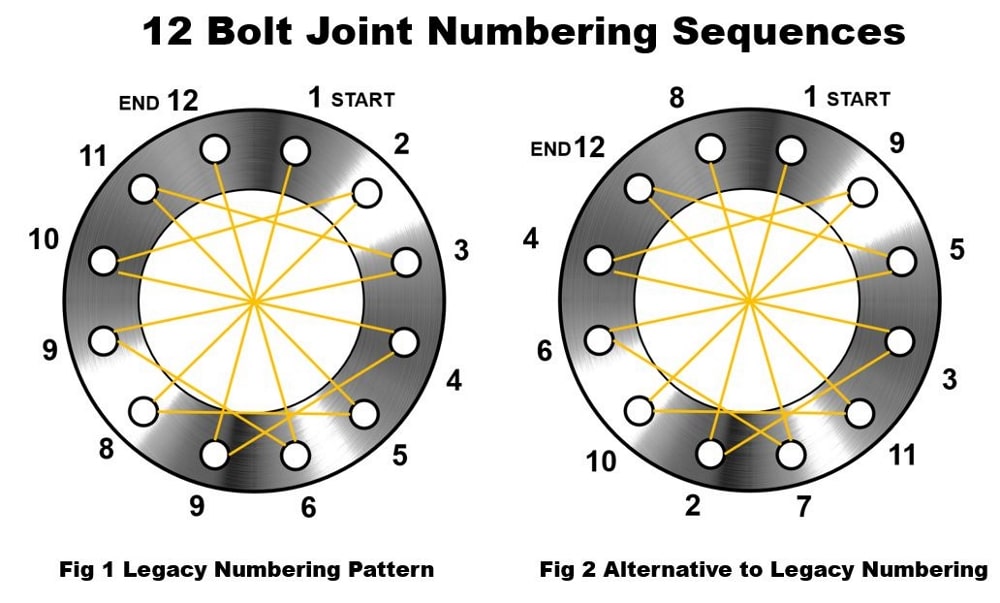

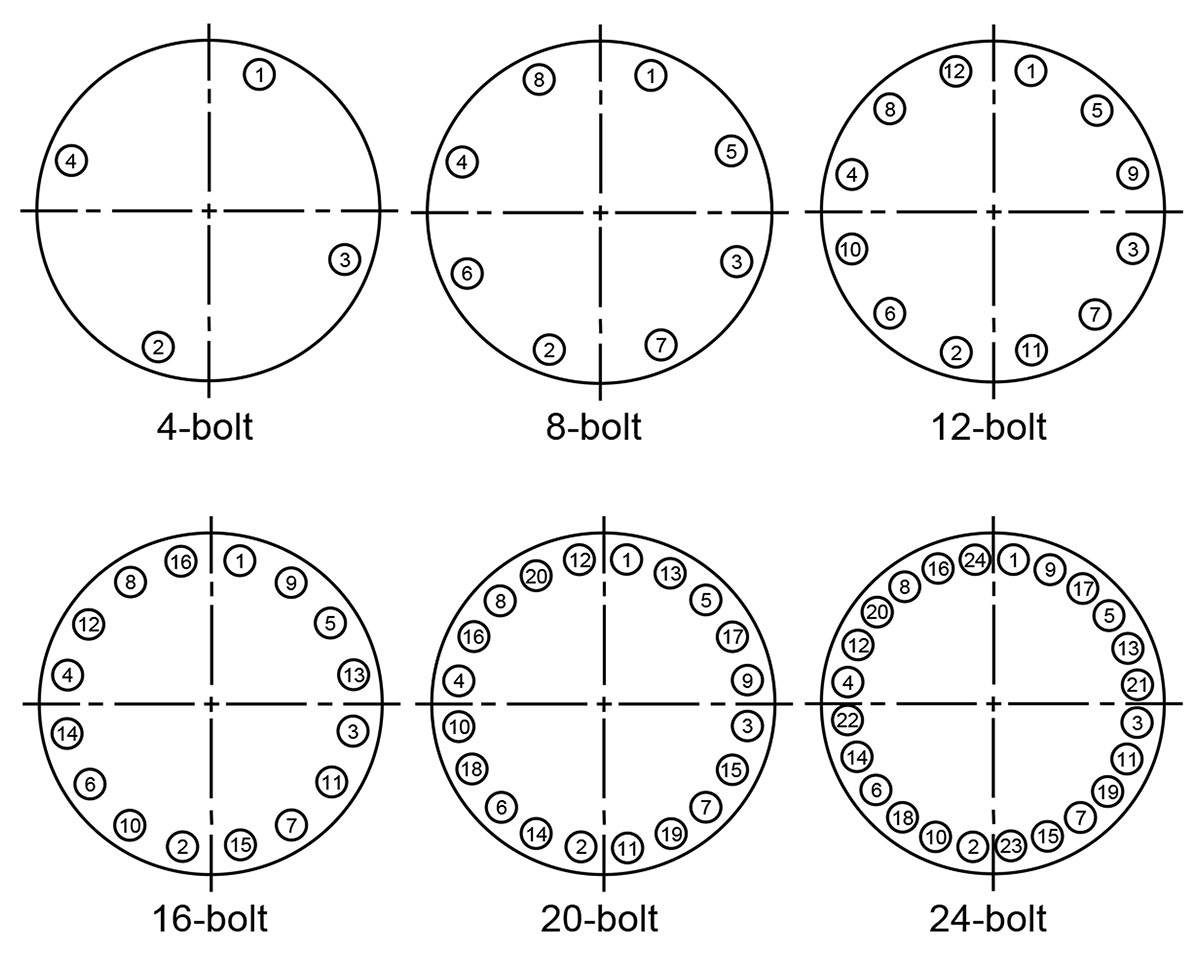

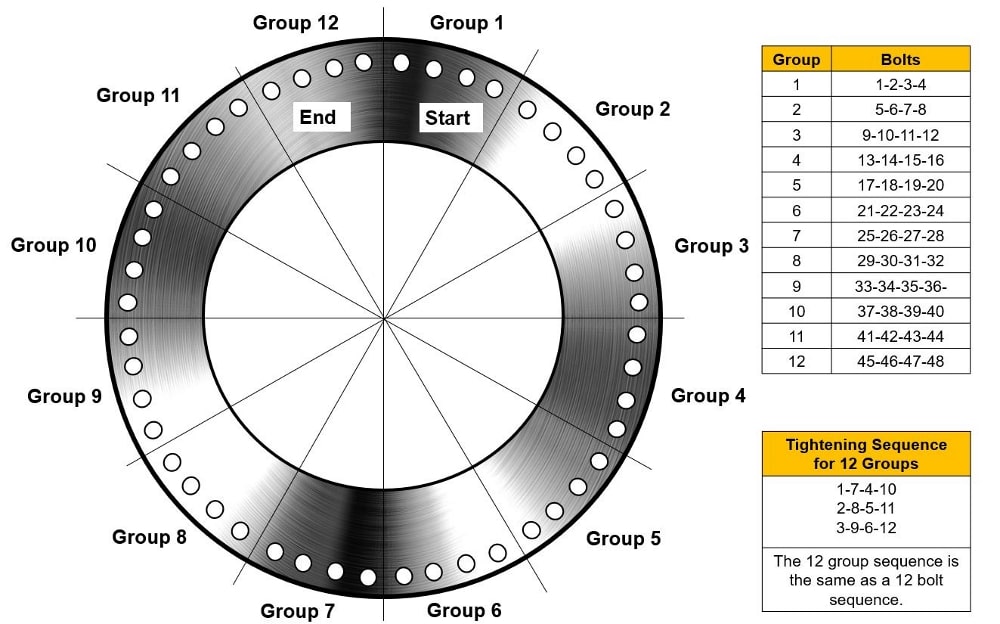

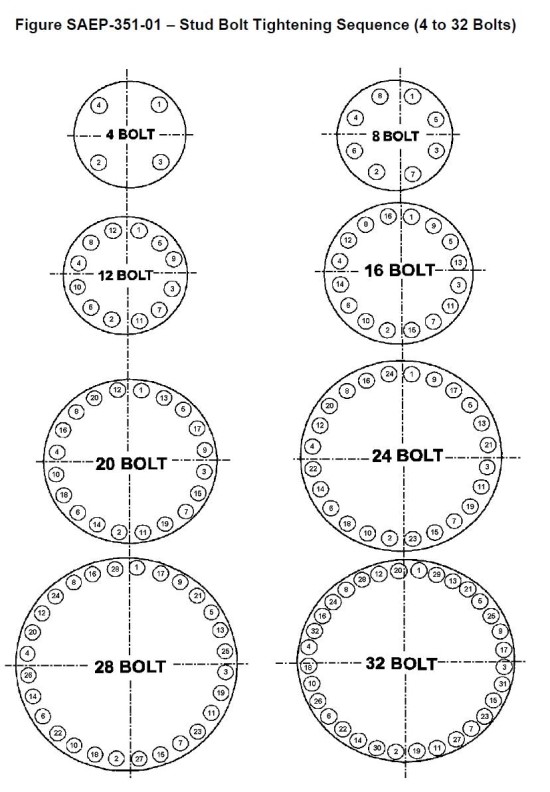

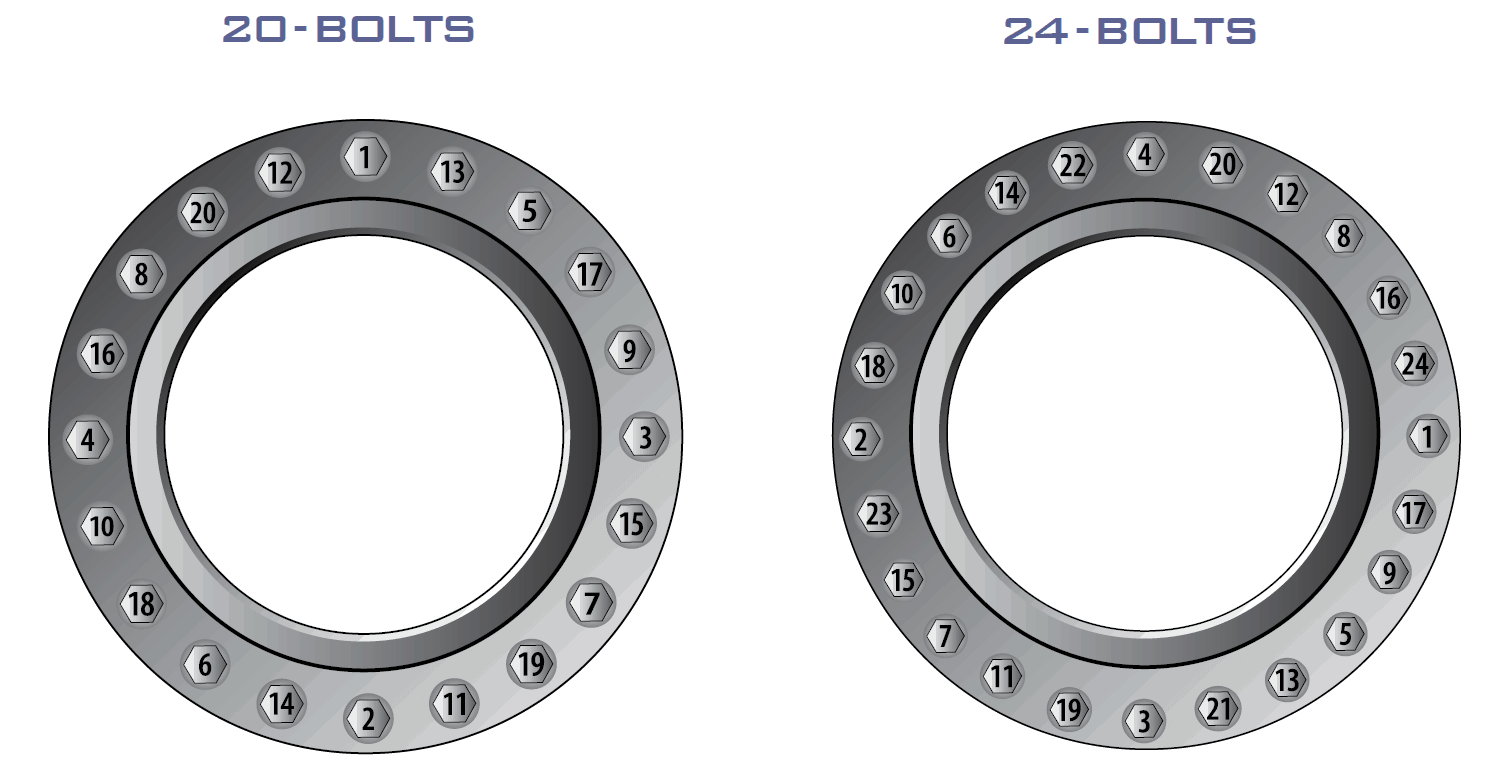

30 Bolt Torque Pattern - Web the specified method of bolt tightening is equally applicable to coated, galvanized and ungalvanized bolts. Web regular maintenance and adherence to manufacturer guidelines will help keep your briggs and stratton engine running smoothly for years to come. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) edge®. Web flange bolt torque patterns. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) flexseal®. The number bolts and tighten two bolts at each number. First snug the bolts all down using this pattern. Web to calculate the torque required to tighten a bolt: Repeat with the torque wrench at 60%. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: Web flange bolt torque patterns. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. ***ramco®manufacturing does not take any responsibility for any of these torque values, they are theoretical values & should be utlilized. Set the torque wrench to 30% of full torque and, using the pattern, tighten each fastener. East pompano beach, fl 33060. Web regular maintenance and adherence to manufacturer guidelines will help keep your briggs and stratton engine running smoothly for years to come. Flanges with 40 bolts or more may use a bolt pattern for half. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Web relaxation of the system (bolts, gasket, and flange) to take. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) jacketed gasket. This gives multiple options for tightening sequences which if followed correctly will help to ensure a leak free flange joint. Using a calibrated torque wrench (manual or hydraulic torque wrench ), flange bolt torque can be measured during flange assembly. Lookup flange bolt torque patterns on your phone in seconds. Web to. Lookup flange bolt torque patterns on your phone in seconds. ***ramco®manufacturing does not take any responsibility for any of these torque values, they are theoretical values & should be utlilized. The number bolts and tighten two bolts at each number. This gives multiple options for tightening sequences which if followed correctly will help to ensure a leak free flange joint.. East pompano beach, fl 33060. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120 0.1250 0.1380 0.1640 0.1900 0.2500 0.3125 0.3750 0.4375 0.5000 0.6250 0.7500 0.8750 1.0000 1.2500 1.5000. Torque to a maximum of 30% of the final torque value in accordance with the torque sequence. Web the specified. Web 20, 12, 8, 16, 24, 32. 1, 33, 25, 17, 9, 5, 13, 21, 29, 3, 35, 27, 19, 11, 7, 15, 23, 31, 2, 34, 26, 18, 10, 6, 14, 22, 30, 4, 36, 28, 20, 12, 8, 16, 24, 32. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) edge®. Web bolt torque is the twisting or turning force applied. Web 39 15 49 12 74 65 70 4726 63 2 8744 21 36. Returns made easyhuge savingshuge selectionfeatured collections Web regular maintenance and adherence to manufacturer guidelines will help keep your briggs and stratton engine running smoothly for years to come. First snug the bolts all down using this pattern. Lookup flange bolt torque patterns on your phone in. K = 0.15 k = 0.17 k = 0.20. Web look up flange bolt sizes and torque patterns in three taps with flange bolt. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120 0.1250 0.1380 0.1640 0.1900 0.2500 0.3125 0.3750 0.4375 0.5000 0.6250 0.7500 0.8750 1.0000 1.2500 1.5000. Web. East pompano beach, fl 33060. Web bolt tightening patterns. ***ramco®manufacturing does not take any responsibility for any of these torque values, they are theoretical values & should be utlilized. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. The number bolts and tighten two bolts at each number. Manufactured in the us3 year warrantypersonalized support Web bolt tightening patterns. 1, 33, 25, 17, 9, 5, 13, 21, 29, 3, 35, 27, 19, 11, 7, 15, 23, 31, 2, 34, 26, 18, 10, 6, 14, 22, 30, 4, 36, 28, 20, 12, 8, 16, 24, 32. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. Determine bolt size — find the diameter and thread pitch of the bolt. 1, 65, 57, 49, 41, 33, 25, 17, 9, 5, 13, 21, 29, 37, 45, 53, 61, 69, 3, 67, 59, 51, 43, 35, 27, 19, 11, 7, 15, 23, 31, 39, 47, 55, 63, 71, 2, 66, 58, 50, 42, 34, 26, 18, 10, 6, 14, 22, 30, 38, 46, 54, 62, 70, 4, 68, 60, 52, 44, 36, 28, 20, 12, 8, 16, 24, 32, 40, 48, 56, 64, 72. Flanges with 40 bolts or more may use a bolt pattern for half. 1, 33, 25, 17, 9, 5, 13, 21, 29, 3, 35, 27, 19, 11, 7, 15, 23, 31, 2, 34, 26, 18, 10, 6, 14, 22, 30, 4, 36, 28, 20, 12, 8, 16, 24, 32. 1, 17, 9, 5, 13, 3, 19, 11, 7, 15, 2, 18, 10, 6, 14, 4, 20, 12, 8, 16. Web 20, 12, 8, 16, 24, 32. Web following the pattern described above, insert the bolts and run up the nuts by hand. Look up torque specification — use a torque chart specific to the bolt's size and material. Web i don't have a tightening sequence picture for you but if you start in the middle of the head and zig zag pattern to the ends you will be okay. Web bolt torque is the twisting or turning force applied to tighten the nut on a bolt. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) Web the specified method of bolt tightening is equally applicable to coated, galvanized and ungalvanized bolts. Consider material strength — adjust for the bolt and mating material's strength. K = 0.15 k = 0.17 k = 0.20. Just enter the flange size, type, and class, and the tool instantly shows the asme values for:

Torque Charts Industrial Bolting and Torque Tools

Printable Bolt Torque Chart

Bolt Torque Patterns Free Patterns Images and Photos finder

Printable Bolt Torque Chart

30 Bolt Torque Sequence

8 Steps to Properly Installing a Gasket Triangle Fluid Controls Ltd.

Torque Charts Industrial Torque Tools

Flange Bolt Torque Sequence UIP International Premium, 53 OFF

Bolted Flange Joints Assembly 네이버 블로그

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

Web Flange Bolt Torque Patterns.

Web Flange Bolt Torque Sequence Www.hswhite.com | 954.785.6760 | Sales@Hswhite.com 1350 South Dixie Hwy.

Learn How To Properly Torque The Head Bolts Of Your Briggs And Stratton Engine Using.

Web Relaxation Of The System (Bolts, Gasket, And Flange) To Take Place.

Related Post: