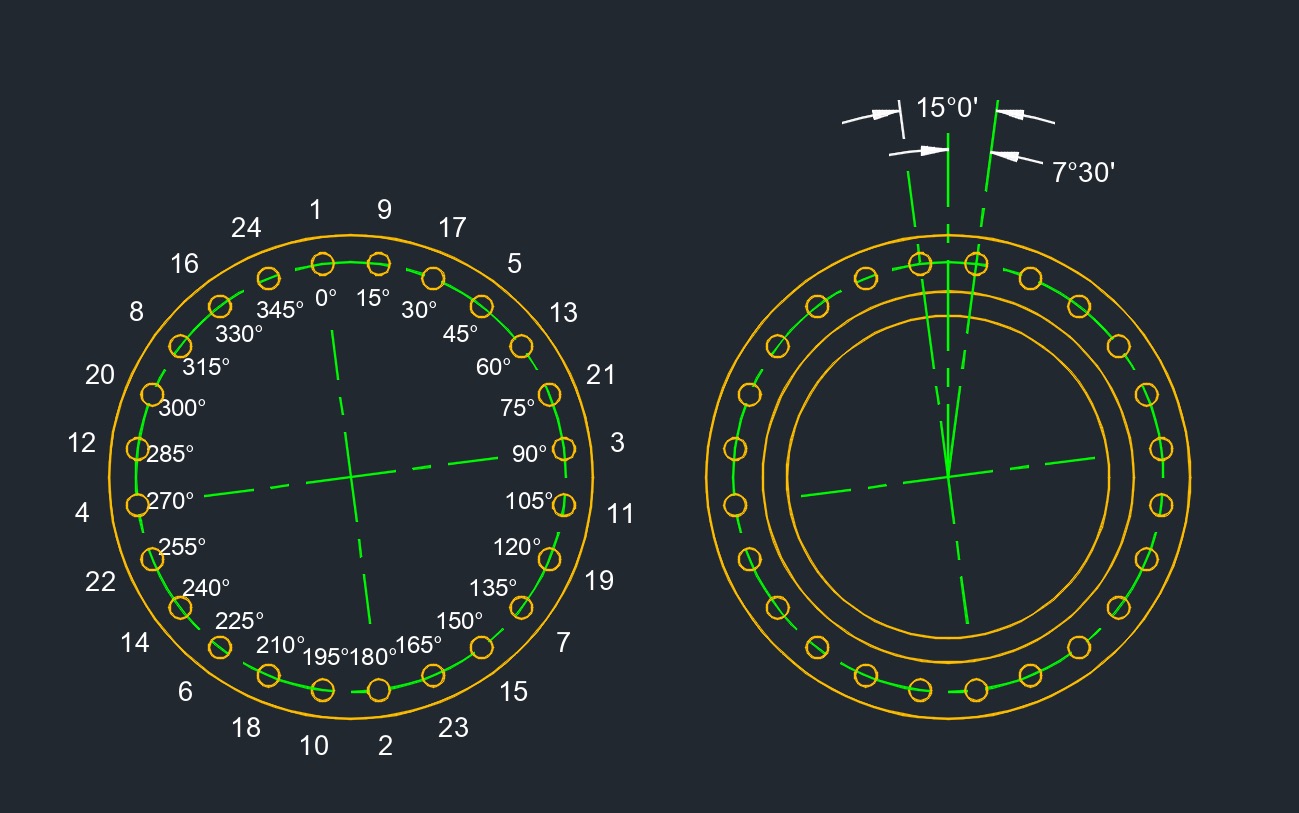

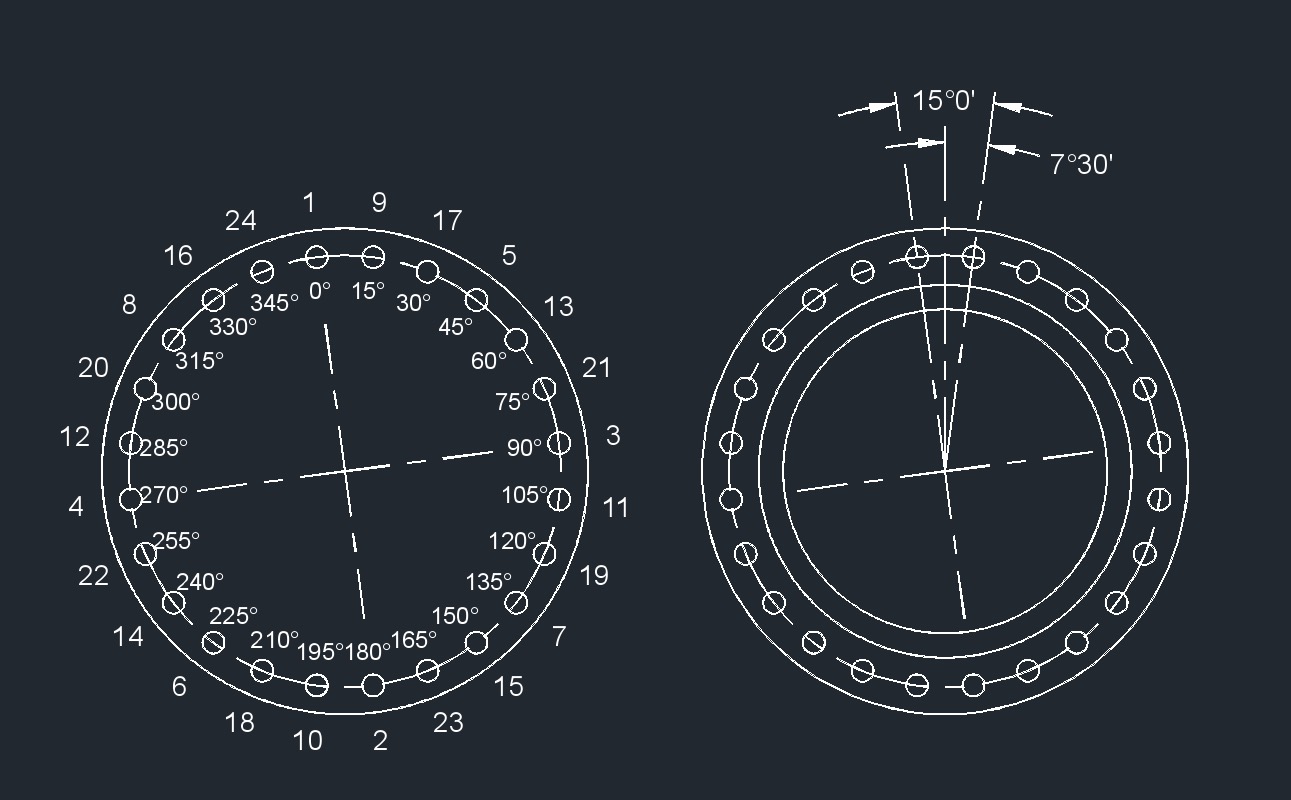

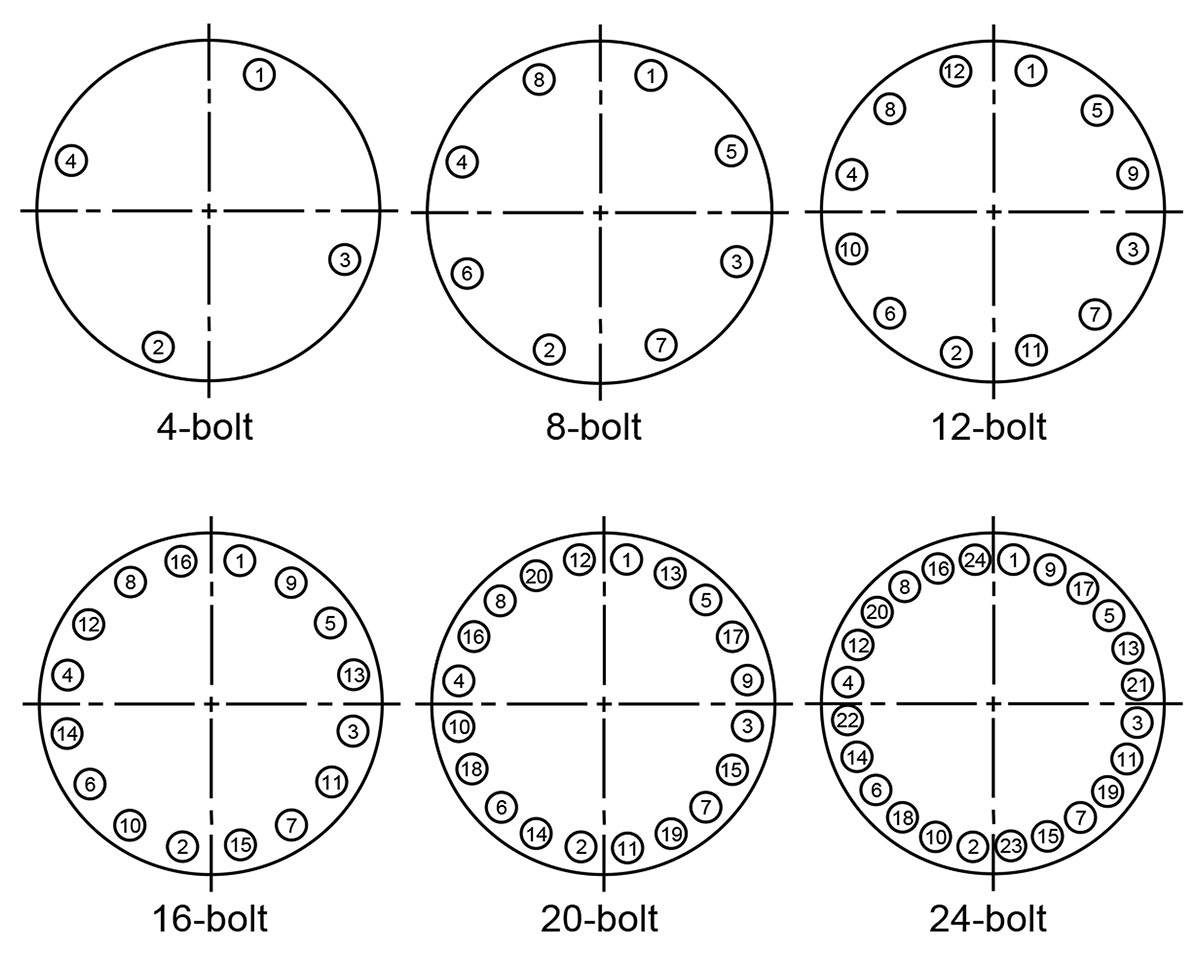

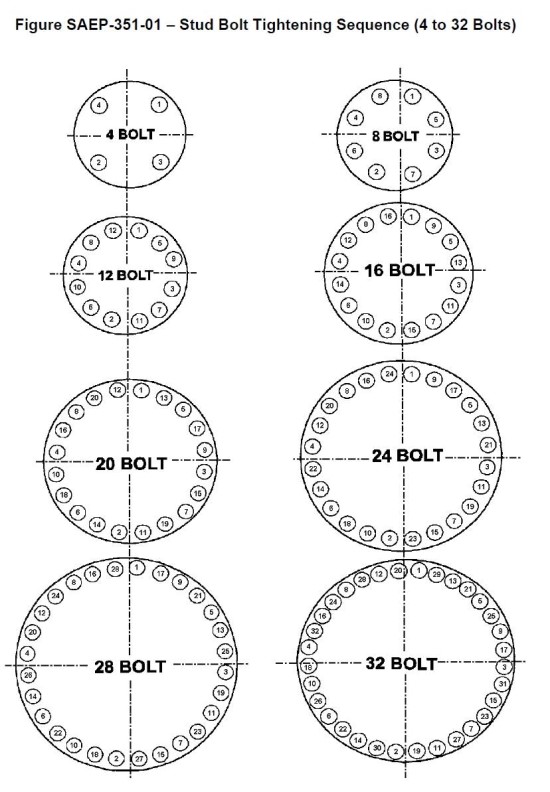

24 Bolt Flange Torque Pattern

24 Bolt Flange Torque Pattern - Based on the users input, the torque calculator. 1, 17, 9, 5, 13, 21, 3, 19, 11, 7, 15, 23, 2, 18, 10, 6, 14, 22, 4, 20, 12, 8, 16, 24. D = bolt diameter in mm. Web bolt tightening patterns. Web 24 bolt torque pattern. Web this paper discusses a method to determine the local flange bending strength of a wide flange member using the yield line method. K = 0.15 k = 0.17 k = 0.20. Web relaxation of the system (bolts, gasket, and flange) to take place. F = bolt load in n. Torque can vary over a 2 to 1 ratio. Web this paper discusses a method to determine the local flange bending strength of a wide flange member using the yield line method. Sealing for a safer and greener tomorrow. Web the user is able to select from ansi/awwa c207 (2013b) flange classes, gasket materials, and flange diameters. Based on the users input, the torque calculator. F = bolt load. Web 24 bolt torque pattern. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120. Web in general, it is not a good idea to specify bolt torque for tightening rubber gaskets on flanges. Research council on structural connections Continue tightening all fasteners until there is no nut. Web the following summarises the most commonly used flange bolt tightening techniques: Torque can vary over a 2 to 1 ratio. Web bolt tightening patterns. When this happens, the bolt fractures. K=dimensionless nut factor or tightening factor. Based on the users input, the torque calculator. Web in general, it is not a good idea to specify bolt torque for tightening rubber gaskets on flanges. When this happens, the bolt fractures. Web 24 bolt torque pattern. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Web relaxation of the system (bolts, gasket, and flange) to take place. F = bolt load in n. 1 17 9 5 13 21 3 19 11 7 15 23 2 18 10 6 14 22 4 20 12 8 16 24. Sealing for a safer. Web this paper discusses a method to determine the local flange bending strength of a wide flange member using the yield line method. When this happens, the bolt fractures. D = bolt diameter in mm. Web in general, it is not a good idea to specify bolt torque for tightening rubber gaskets on flanges. The proposed design method includes the. East pompano beach, fl 33060. D = bolt diameter in mm. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120. K=dimensionless nut factor or tightening factor. 1 17 9 5 13 21 3 19 11 7 15 23 2 18 10 6 14 22 4 20 12 8 16. Web relaxation of the system (bolts, gasket, and flange) to take place. The proposed design method includes the. Web in general, it is not a good idea to specify bolt torque for tightening rubber gaskets on flanges. Web this paper discusses a method to determine the local flange bending strength of a wide flange member using the yield line method.. When this happens, the bolt fractures. East pompano beach, fl 33060. 1, 17, 9, 5, 13, 21, 3, 19, 11, 7, 15, 23, 2, 18, 10, 6, 14, 22, 4, 20, 12, 8, 16, 24. F = bolt load in n. Continue tightening all fasteners until there is no nut. Web in the metric system, torque applied, t = (k.d.f)/1000. 1 17 9 5 13 21 3 19 11 7 15 23 2 18 10 6 14 22 4 20 12 8 16 24. Torque can vary over a 2 to 1 ratio. When this happens, the bolt fractures. Uip supplies gaskets of all types & sizes for many industrial. When this happens, the bolt fractures. Torque can vary over a 2 to 1 ratio. K=dimensionless nut factor or tightening factor. The final tightening pass should be completed using the torque. Continue tightening all fasteners until there is no nut. Based on the users input, the torque calculator. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. Web the following summarises the most commonly used flange bolt tightening techniques: F = bolt load in n. Web relaxation of the system (bolts, gasket, and flange) to take place. K = 0.15 k = 0.17 k = 0.20. D = bolt diameter in mm. Web the user is able to select from ansi/awwa c207 (2013b) flange classes, gasket materials, and flange diameters. Web bolt tightening patterns. East pompano beach, fl 33060. 1, 17, 9, 5, 13, 21, 3, 19, 11, 7, 15, 23, 2, 18, 10, 6, 14, 22, 4, 20, 12, 8, 16, 24.

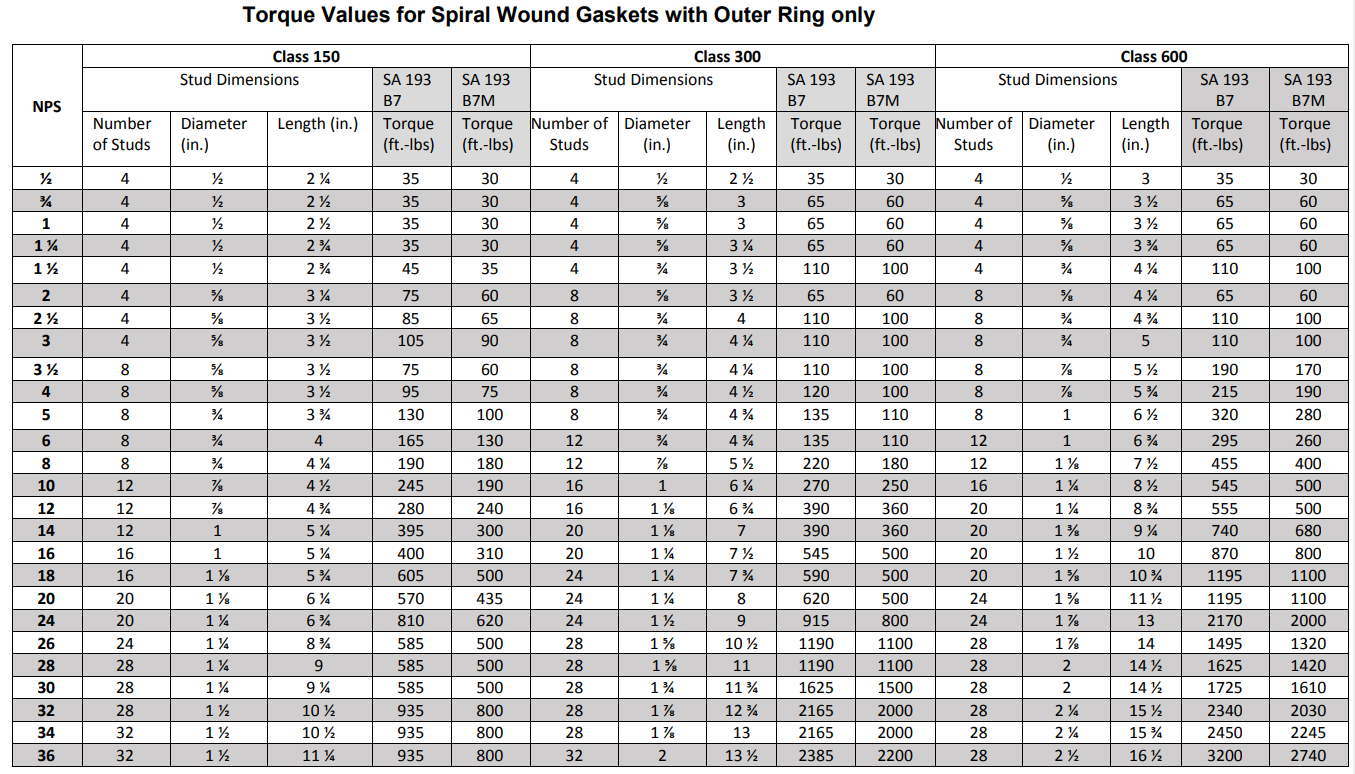

Torque Charts Industrial Bolting and Torque Tools

Torque Table For Bolt Tightening 12 9 Elcho Table

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

Torque Charts Industrial Bolting and Torque Tools

Flange Bolt Torque Sequence Chart A Visual Reference of Charts Chart

Torque Sequence For 24 Bolt Flange New Images Bolt

Torque Sequence For 24 Bolt Flange New Images Bolt

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Torque Sequence For 24 Bolt Flange New Images Bolt

1 17 9 5 13 21 3 19 11 7 15 23 2 18 10 6 14 22 4 20 12 8 16 24.

The Proposed Design Method Includes The.

Research Council On Structural Connections

Uip Supplies Gaskets Of All Types & Sizes For Many Industrial Applications.

Related Post: