20 Bolt Torque Pattern

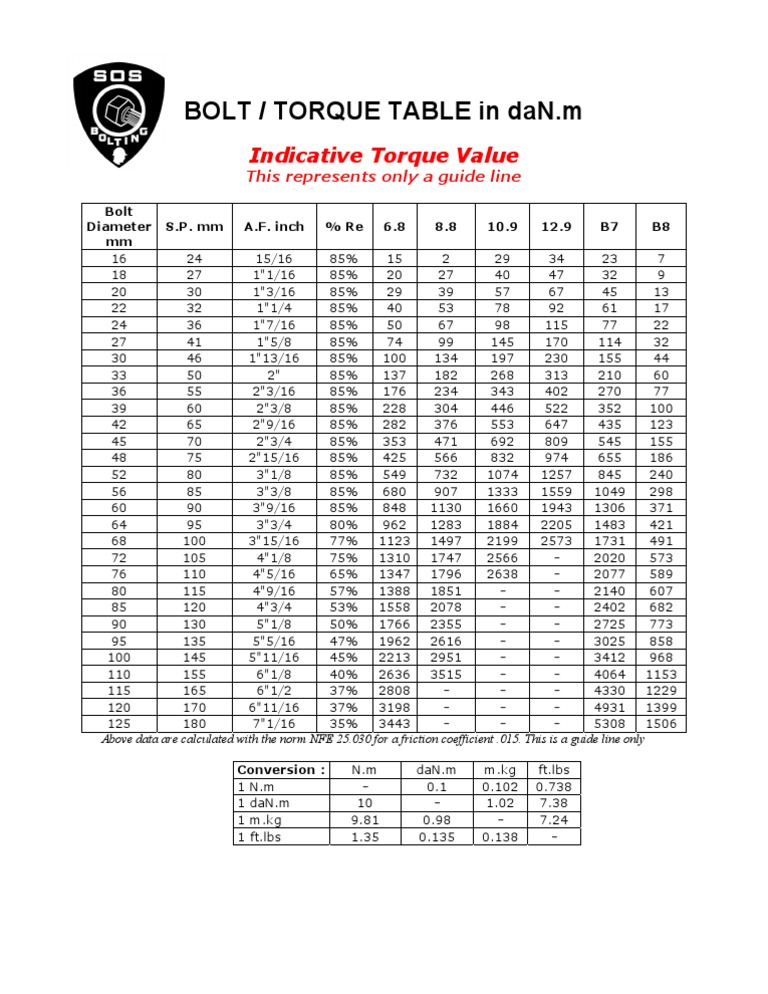

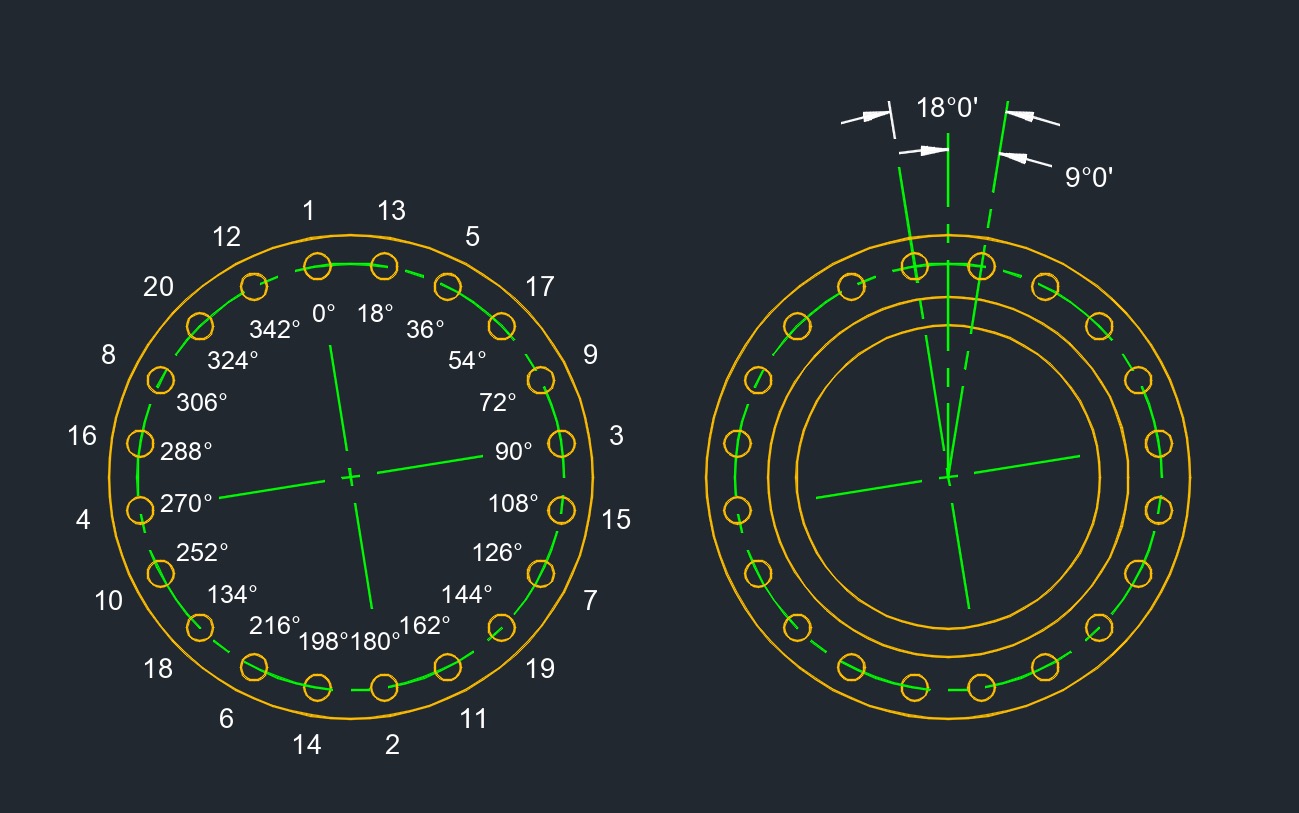

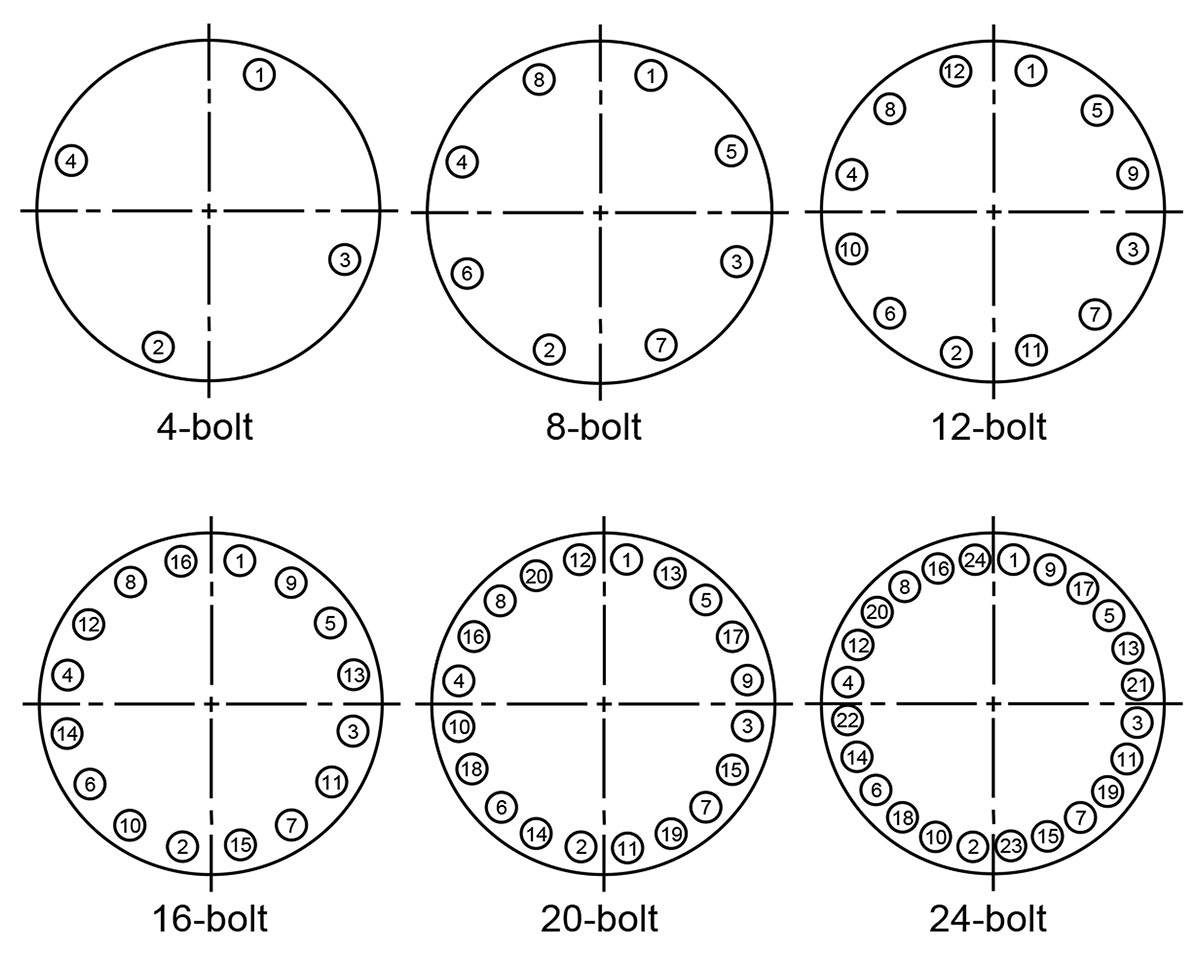

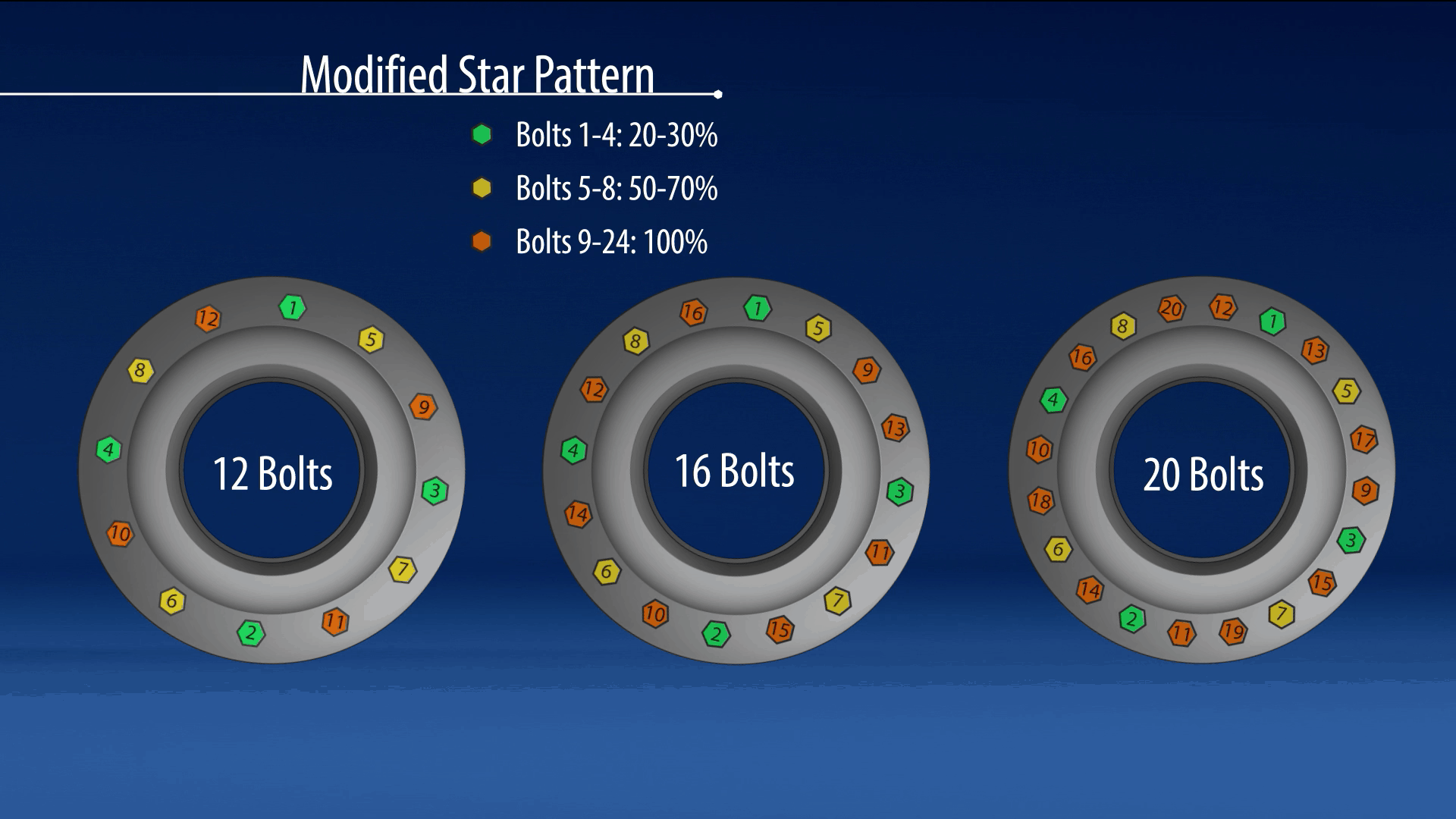

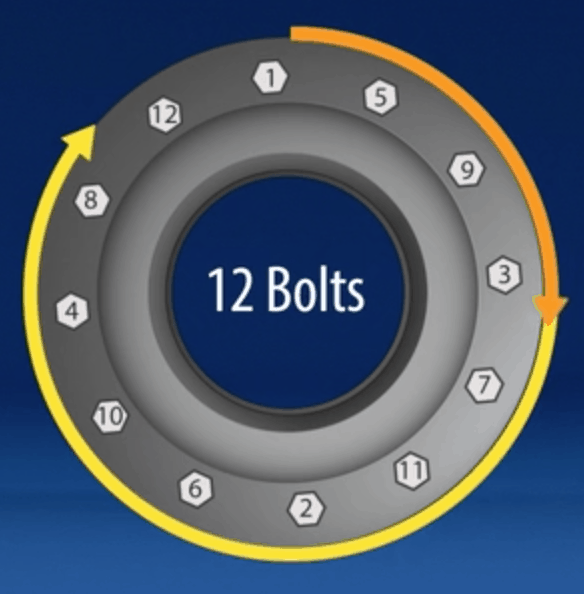

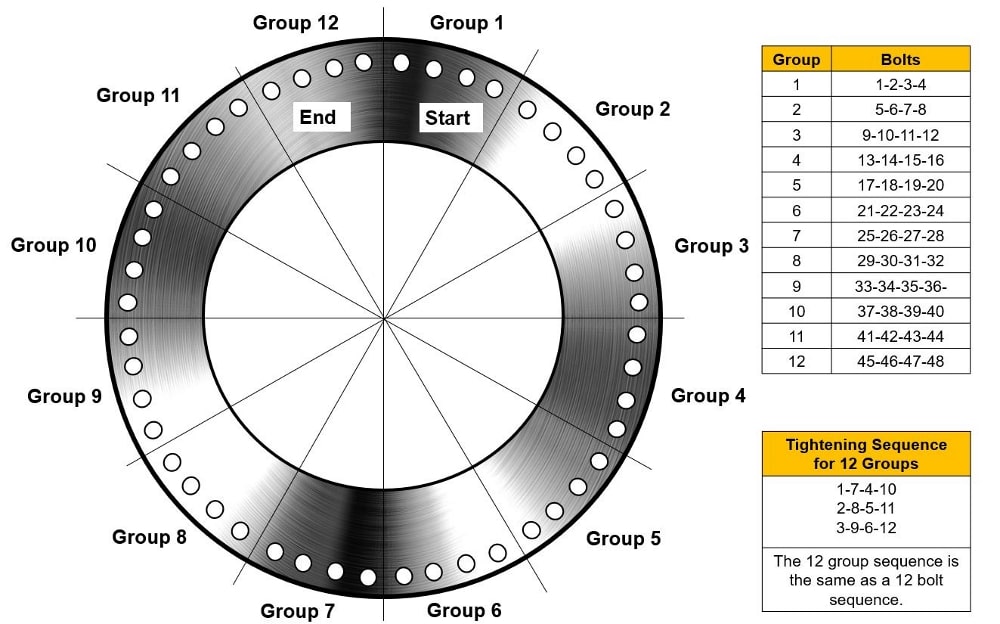

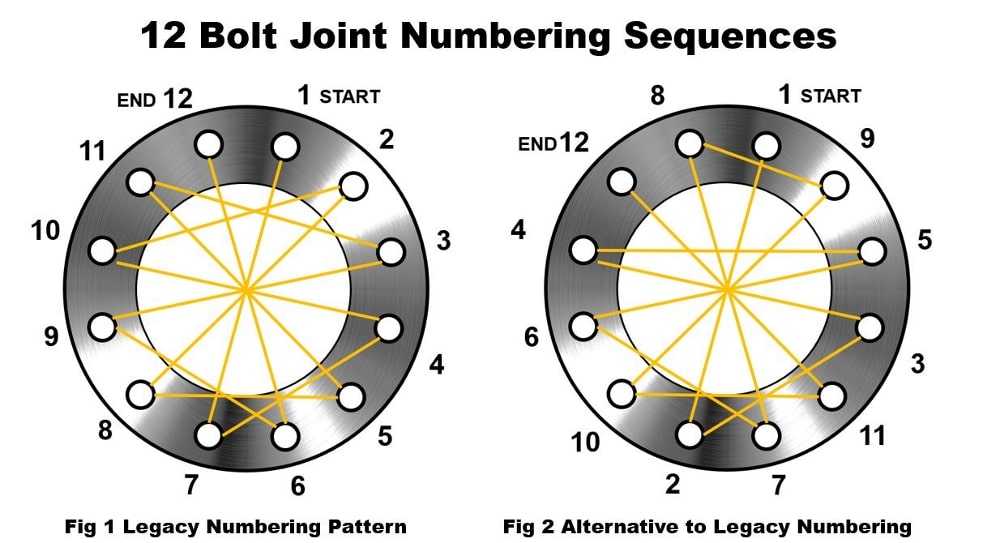

20 Bolt Torque Pattern - Web flange joints require proper tightening to avoid leakage. K = 0.15 k = 0.17 k = 0.20. For dry bolts, the values should be increased by 30%. Bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Pause the tightening process for a minimum of 20 minutes to 4 hours. 1 17 9 5 13 3 19 11 7 15 2 18 10 6 14 4 20 12 8 16. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. Web the torque setting now remains at full value for the remaining tightening. Determine bolt size — find the diameter and thread pitch of the bolt. Web the torque setting now remains at full value for the remaining tightening. A minimum of two complete 360 degree passes should be made or until there is no nut movement. Determine bolt size — find the diameter and thread pitch of the bolt. Bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Web flange bolt. Pause the tightening process for a minimum of 20 minutes to 4 hours. Web this table shows values for threads that have been lightly oiled and the tension is 70% of yield strength. Web 12 bolt torque pattern for flanges and more. Web 20” 1 1/4” 1360 1000 24” 1 1/2” 1900 1400 recommended torque bolt (nm) (lb.ft) 1/2” 40. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. 1, 17, 9, 5, 13, 3, 19, 11, 7, 15, 2, 18, 10, 6, 14, 4, 20, 12, 8, 16. 1 17 9 5 13 3 19 11 7 15 2 18 10 6 14 4 20 12 8 16. A minimum of two complete 360. Uip supplies gaskets of all types & sizes for many industrial applications. Web to calculate the torque required to tighten a bolt: A minimum of two complete 360 degree passes should be made or until there is no nut movement. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Web flange joints require proper tightening to avoid leakage. Garlock sealing technologies an enpro industries company. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Determine bolt size — find the diameter and thread pitch of the bolt. Look up torque specification — use a torque. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. Garlock sealing technologies an enpro industries company. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. A minimum of two complete 360 degree passes should be made or until there is no nut movement. For dry bolts, the values should be increased by 30%. Web garlock sealing technologies an enpro industries company. Lookup flange bolt torque patterns on. Bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Pause the tightening process for a minimum of 20 minutes to 4 hours. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Web 20 bolt torque pattern. Web 20” 1 1/4” 1360 1000 24” 1 1/2” 1900 1400 recommended torque bolt (nm) (lb.ft) 1/2” 40 30 3/4” 5/8” 80 60 1” 5/8” 120 90 1 1/4” 5/8” 120 90 3/4” 220 160 2” 5/8” 120 90 3/4” 160 120 3” 3/4” 240 180 4”. Web 20” 1 1/4” 1360 1000 24” 1 1/2” 1900 1400 recommended torque bolt (nm) (lb.ft) 1/2” 40 30 3/4” 5/8” 80 60 1” 5/8” 120 90 1 1/4” 5/8” 120 90 3/4” 220 160 2” 5/8” 120 90 3/4” 160 120 3” 3/4” 240 180 4” 7/8” 410 300 5” 1” 610 450. Determine bolt size — find the. Web to calculate the torque required to tighten a bolt: Web 20 bolt torque pattern. For dry bolts, the values should be increased by 30%. Bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. A minimum of two complete 360 degree passes should be made or until there is no nut movement. Web 20 bolt torque pattern. 1, 17, 9, 5, 13, 3, 19, 11, 7, 15, 2, 18, 10, 6, 14, 4, 20, 12, 8, 16. Web flange joints require proper tightening to avoid leakage. East pompano beach, fl 33060. Look up torque specification — use a torque. Web flange bolt torque patterns. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Determine bolt size — find the diameter and thread pitch of the bolt. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Web to calculate the torque required to tighten a bolt: Recommended torque values lubricated stud bolts w/0.15 friction value. Pause the tightening process for a minimum of 20 minutes to 4 hours. Garlock sealing technologies an enpro industries company. 1 17 9 5 13 3 19 11 7 15 2 18 10 6 14 4 20 12 8 16. Uip supplies gaskets of all types & sizes for many industrial applications.

Bolt Tightening Procedure

8 Steps to Properly Installing a Gasket Triangle Fluid Controls Ltd.

Bolt Tightening Sequence and Restrictions Hex Technology

20 Bolt Flange Torque Pattern PDF

Bolt Tightening Sequence and Restrictions Hex Technology

Printable Bolt Torque Chart

Torque Charts Industrial Bolting and Torque Tools

Flange Bolt Torque Sequence UIP International Premium, 53 OFF

Bolt Tightening Flange Torque Sequence Chart

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

Web Garlock Sealing Technologies An Enpro Industries Company.

#1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120.

Bolt Tightening Sequence, Or Torque Sequence, Is Defined In The Torque Tightening Procedure.

Web The Torque Setting Now Remains At Full Value For The Remaining Tightening.

Related Post: