16 Bolt Torque Pattern

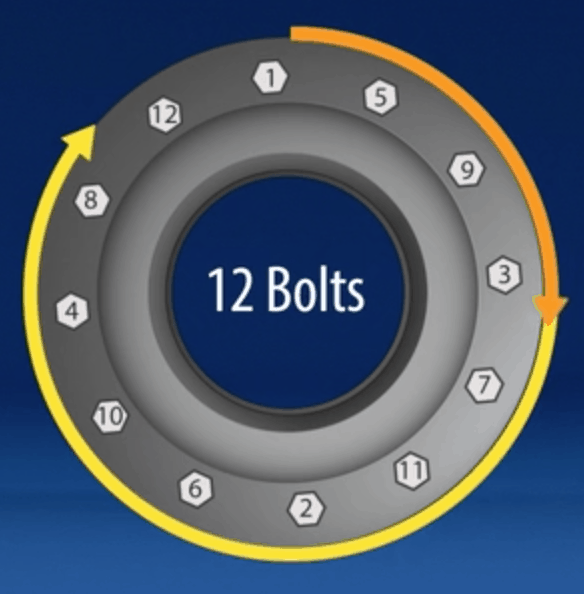

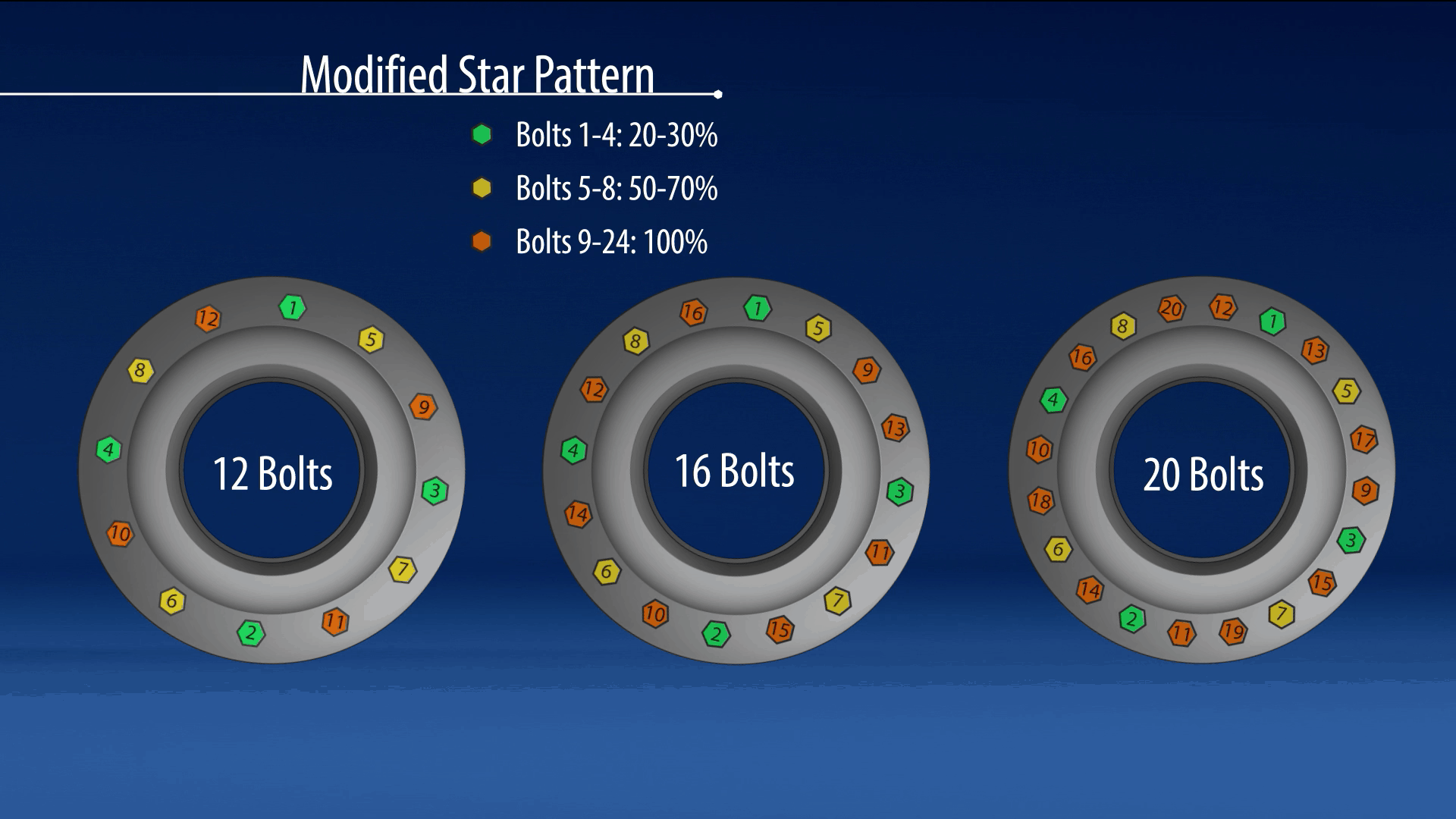

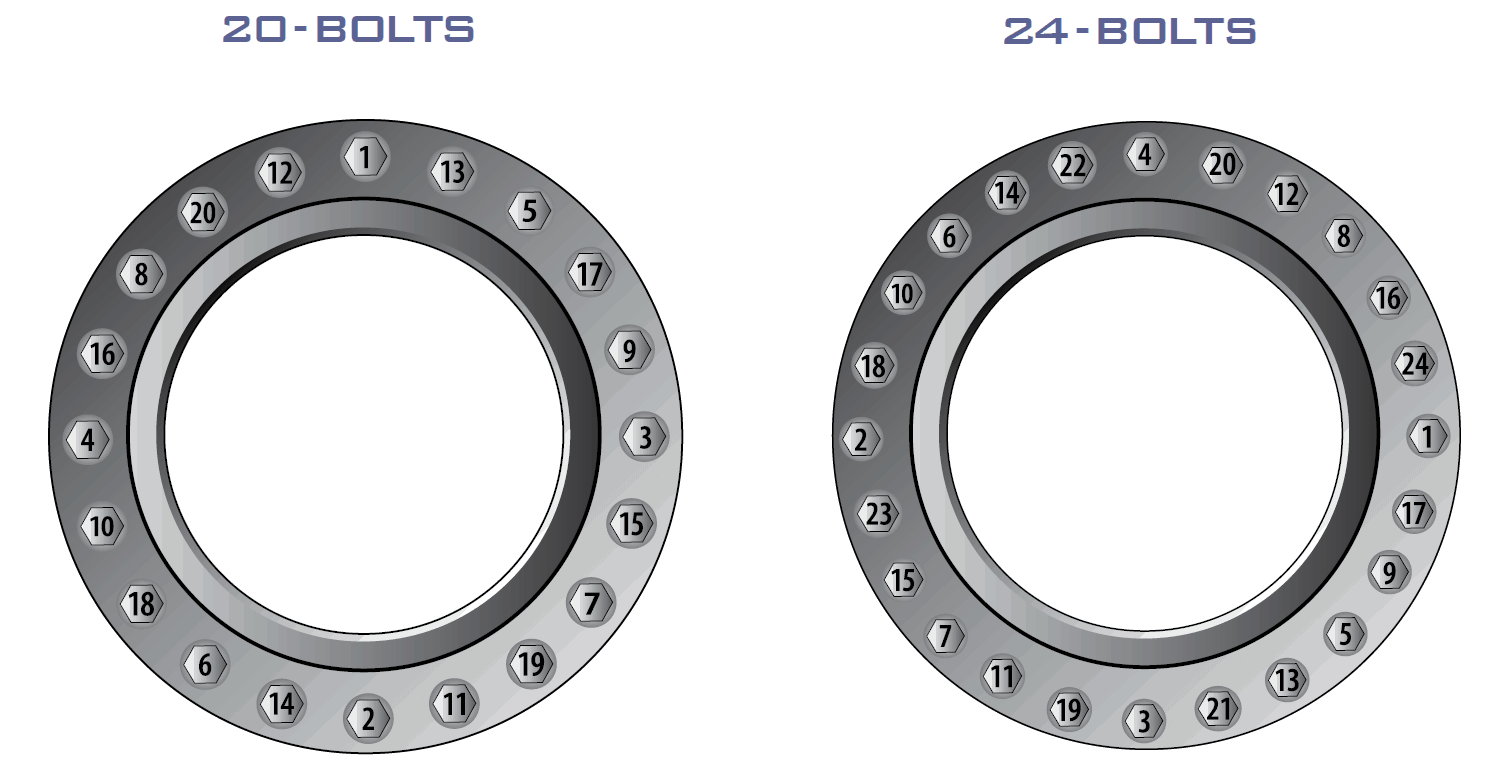

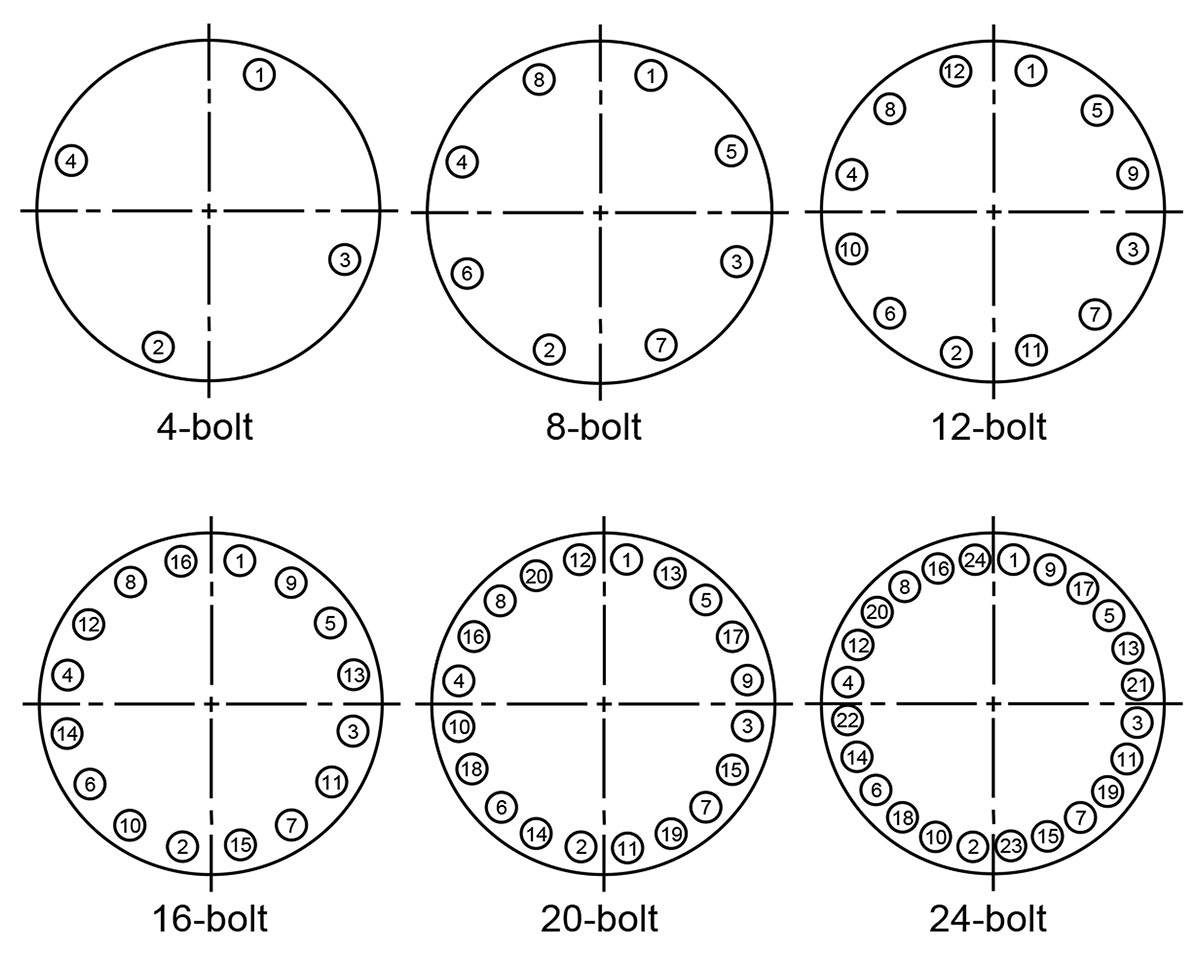

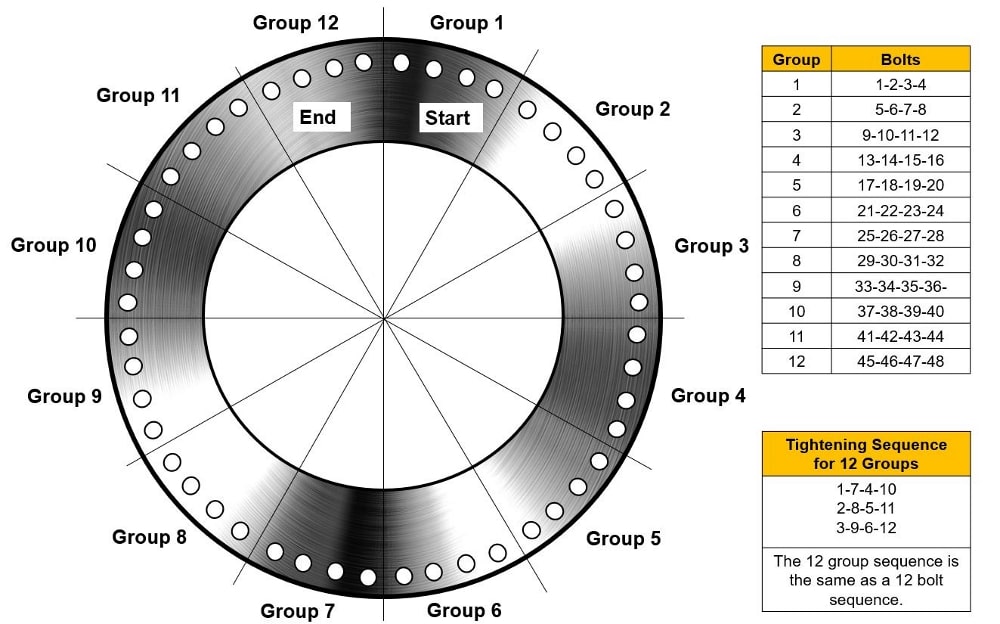

16 Bolt Torque Pattern - Bolt torque chart reference guides include grade 2, b7, a307, a325, grade 8, a490, and grade 5. Torque calculations are based on the simplified formula explained in the current version. The table below shows the torque sequence for flanges with 4 to 32 bolts. Torque has been converted into ft/lbs by dividing the result of the formula by 12; Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. Bolt tightening sequence to follow. Web us recommended bolt torque. Bolt pattern and torque specification. Aft fasteners is your trusted source for fastener. Web welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under normal assembly conditions. Web welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under normal assembly conditions. Number of bolt / stud. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange. Bolt torque chart reference guides include grade 2, b7, a307, a325, grade 8, a490, and grade 5. Check that gasket is getting compressed uniformly. Then hand tighten till they are snug against the Bolt tightening sequence to follow. Web us recommended bolt torque. Instant flange bolt sizes and torque patterns: Aft fasteners is your trusted source for fastener. On standard astm a193 grade b7 studs were in a fairly consistent range from 0.16 to 0.18, regardless of. Web keep repeating until every bolt has been tightened. Alternative assembly pattern #2 quadrant pattern. Instant flange bolt sizes and torque patterns: 1 bolt tightening pattern from ansi/awwa 604 (2017b) ansi/awwa c604 (2017b) provides guidance on various tightening patterns that can be. Aft fasteners is your trusted source for fastener. Bolt torque chart reference guides include grade 2, b7, a307, a325, grade 8, a490, and grade 5. Web this is achieved because not every bolt. Torque to a maximum of 60% of the final torque value. This pattern follows a square quadrant sequence and is used on flanges with 16 bolts or more. All calculations are for coarse thread series (unc). Torque to a maximum of 30% of the final torque value in accordance with the torque sequence. Then hand tighten till they are snug. Torque calculations are based on the simplified formula explained in the current version. East pompano beach, fl 33060. Web 10 bolts 16 bolts suggested seating torques (foot lbs) for end caps and flanges using grade 8 socket head cap screws. Start the tightening procedure by lubricating the nuts and bolts. On standard astm a193 grade b7 studs were in a. Set the torque wrench to 30% of full torque and, using the pattern, tighten each fastener. Torque has been converted into ft/lbs by dividing the result of the formula by 12; Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along. Torque to a maximum of 30% of the final torque value in accordance with the torque sequence. Web 10 bolts 16 bolts suggested seating torques (foot lbs) for end caps and flanges using grade 8 socket head cap screws. The remaining 90% is lost due various forms of friction that occur during. Number of bolt / stud. Alternative assembly pattern. Web recommended torque values lubricated stud bolts w/0.15 friction value nominal quantity bolt nominal quantity bolt nominal quantity bolt pipe size of bolts diameter min max pipe size of bolts diameter min max pipe size of bolts diameter min max 1/2 4 1/2 40 50 1/2 4 1/2 80 90 1/2 4 1/2 80 90 3/4 4 1/2 40 50. Torque to a maximum of 60% of the final torque value. It is estimated that only about 10% of the tightening torque actually results in useful bolt tensioning. The table below shows the torque sequence for flanges with 4 to 32 bolts. Check that gasket is getting compressed uniformly. Torque calculations are based on the simplified formula explained in the. Check that gasket is getting compressed uniformly. 9702365 • as 06/14 torque poster. Bolt torque chart reference guides include grade 2, b7, a307, a325, grade 8, a490, and grade 5. Web 0.5 4 0.50 16 47 9 52 8 42 9 37 18 53 0.75 4 0.50 22 60 12 60 11 54 13 60 25 60 1 4 0.50 30 60 15 60 13 60 17 60 27 60. It is estimated that only about 10% of the tightening torque actually results in useful bolt tensioning. Torque calculations are based on the simplified formula explained in the current version. All calculations are for coarse thread series (unc). Web keep repeating until every bolt has been tightened. Torque has been converted into ft/lbs by dividing the result of the formula by 12; East pompano beach, fl 33060. Alternative assembly pattern #2 quadrant pattern. The specification for this bolt fixing says the clamping force needs to be 25,000 lbs. (the app requires minimum storage space overall) 2. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. The table below shows the torque sequence for flanges with 4 to 32 bolts. Metric bolt sizes seating torque in foot lbs.

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Bolt Tightening Sequence and Restrictions Hex Technology

Bolt Tightening Sequence and Restrictions Hex Technology

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

8 Steps to Properly Installing a Gasket Triangle Fluid Controls Ltd.

16 Bolt Torque Pattern

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

Torque Charts Industrial Bolting and Torque Tools

Flange Bolt Torque Sequence UIP International Premium, 53 OFF

Bolting Patterns Westorc

1 Bolt Tightening Pattern From Ansi/Awwa 604 (2017B) Ansi/Awwa C604 (2017B) Provides Guidance On Various Tightening Patterns That Can Be.

The Remaining 90% Is Lost Due Various Forms Of Friction That Occur During.

Repeat With The Torque Wrench At 60%.

For Those Who Need To Download An Image (The Top Graphic Is Svg) We Include A High Resolution Image Of The 16 Bolt Torque Sequence Below.

Related Post: