12 Bolt Torque Pattern

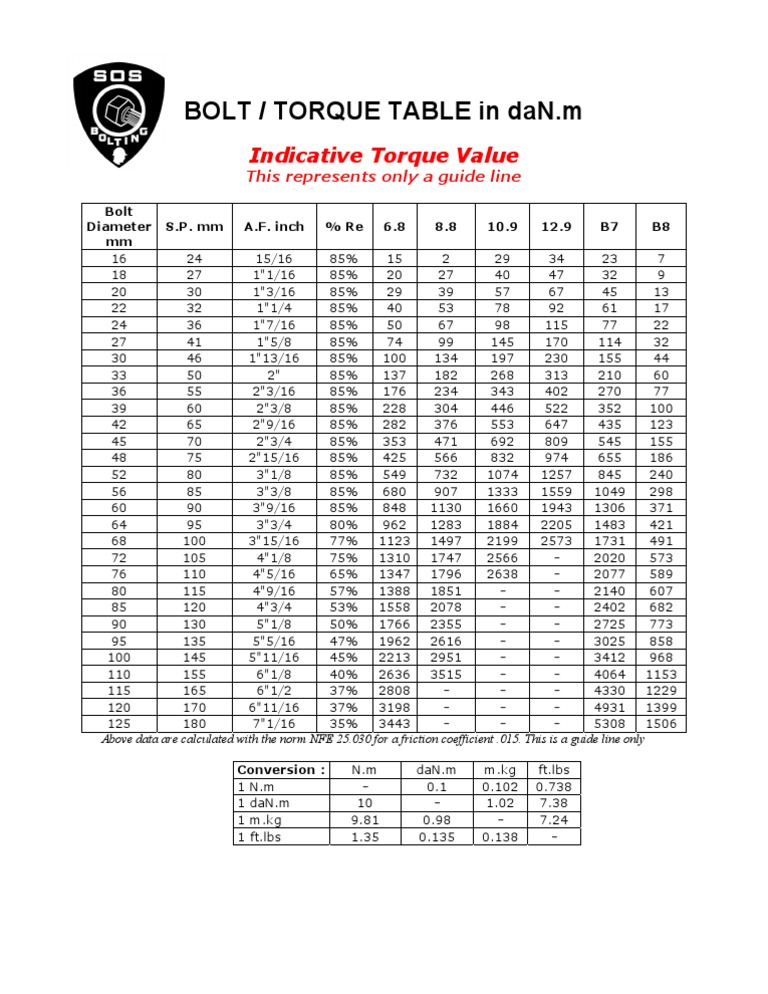

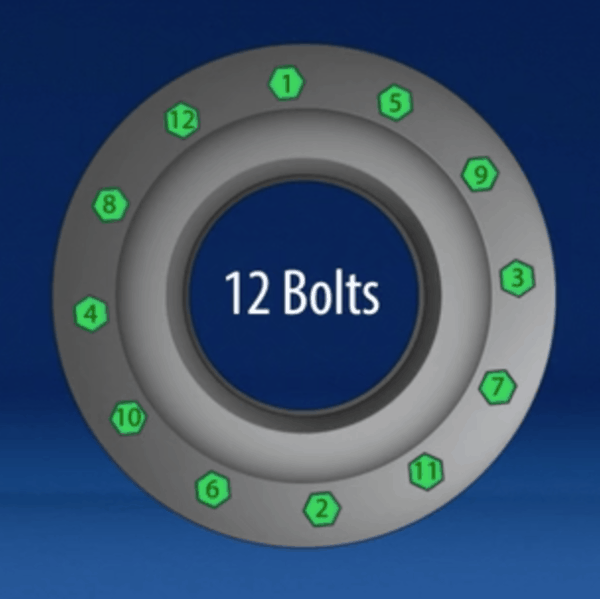

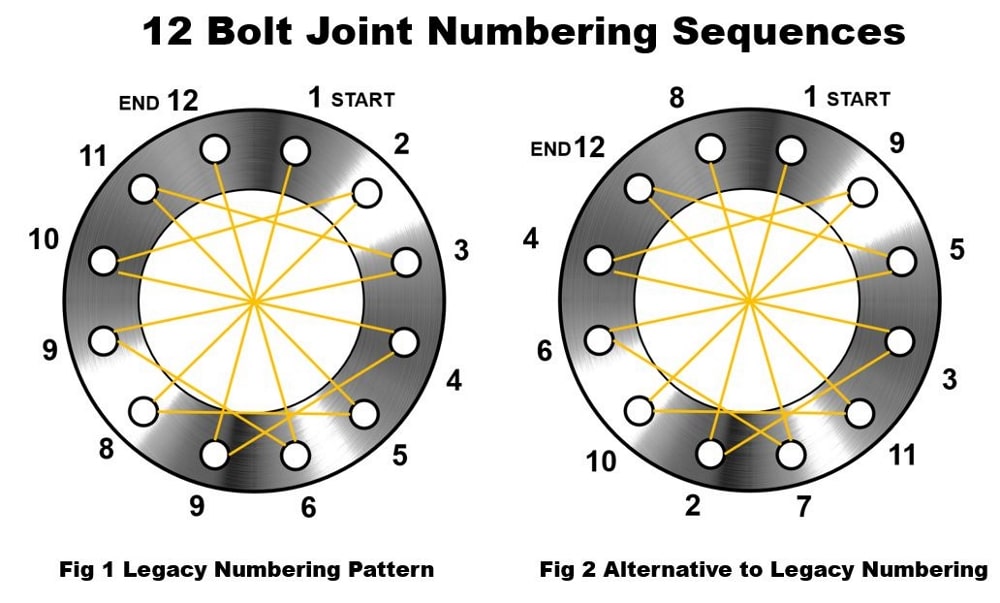

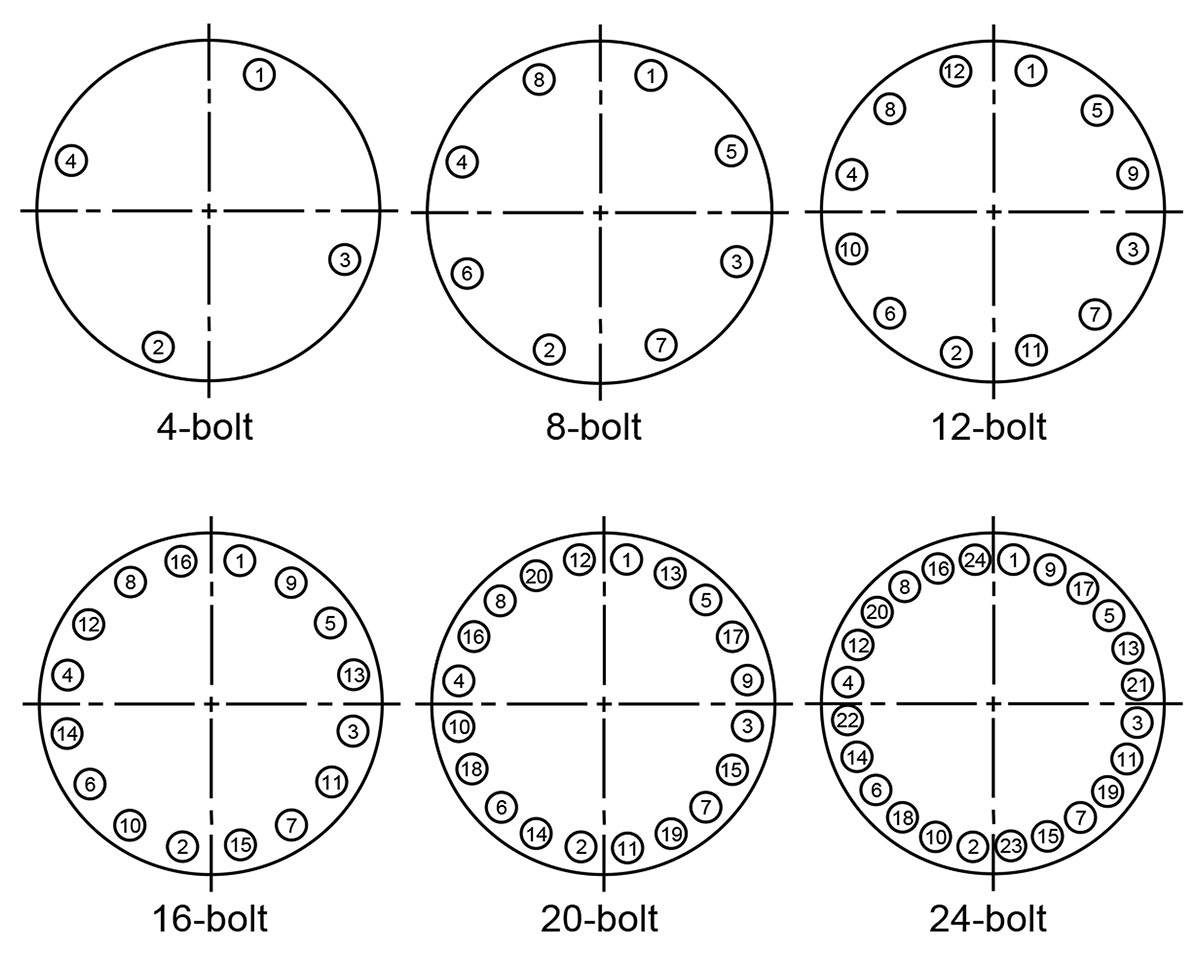

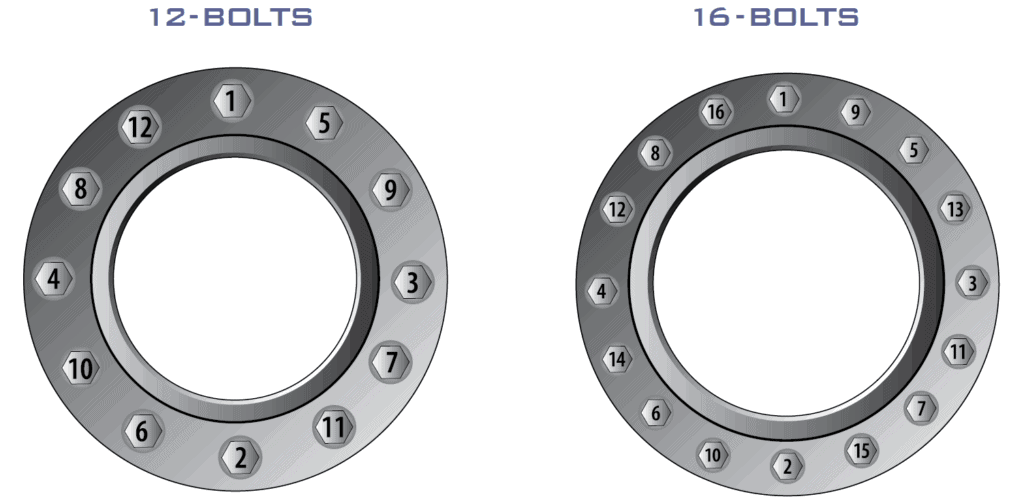

12 Bolt Torque Pattern - F = bolt load in n. D = bolt diameter in mm. Web 12 bolt flanges and more: Shown is the bolt tightening sequences for typical circular flanges. Recommended torque values lubricated stud bolts w/0.15 friction value. Web flange bolt torque patterns. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Lookup flange bolt torque patterns on your phone in seconds. Determine bolt size — find the diameter and thread pitch of the bolt. There are two aspects to consider: Web flange bolt torque patterns. Web flange joints require proper tightening to avoid leakage. Recommended torque values lubricated stud bolts w/0.15 friction value. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Web 12 bolt flanges and more: Web to calculate the torque required to tighten a bolt: The bolt pattern and the tightening sequence. F = bolt load in n. Web 12 bolt flanges and more: Diameter are based on 30 ksi yield strength. 1, 9, 5, 3, 11, 7, 2, 10, 6, 4, 12, 8. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. D = bolt diameter in mm. Web 12 bolt flanges and more: Web these metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and. Diameter are based on 30 ksi yield strength. ***ramco®manufacturing does not take any responsibility for any of these torque values, they are theoretical values & should be. Based on the users input, the torque calculator generates a. Recommended torque values lubricated stud bolts w/0.15 friction value. Web it’s also important to avoid deforming the flange faces. East pompano beach, fl 33060. ***ramco®manufacturing does not take any responsibility for any of these torque values, they are theoretical values & should be. 9/16 12 4912 35 39 46 11599 65 82 92 109. 9702365 • as 06/14 torque poster. There are two aspects to consider: Web flange joints require proper tightening to avoid leakage. Lookup flange bolt torque patterns on your phone in seconds. Diameter are based on 30 ksi yield strength. Based on the users input, the torque calculator generates a. Web torque values for bolts greater than 1.1/2 in. Web 12 bolt flanges and more: Lookup flange bolt torque patterns on your phone in seconds. Web in the metric system, torque applied, t = (k.d.f)/1000. D = bolt diameter in mm. Bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Diameter are based on 30 ksi yield strength. Shown is the bolt tightening sequences for typical circular flanges. K=dimensionless nut factor or tightening factor. The bolt’s class indicates its material strength,. 9702365 • as 06/14 torque poster. Web bolt size tpi proof load (lbs) 1 clamp load (lbs) 2 tightening torque (ft lbs) galv+waxed galv plain; 1, 9, 5, 3, 11, 7, 2, 10, 6, 4, 12, 8. Bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Web it’s also important to avoid deforming the flange faces. Based on the users input, the. Web flange joints require proper tightening to avoid leakage. Look up torque specification — use a torque. East pompano beach, fl 33060. Based on the users input, the torque calculator generates a. Web the user is able to select from ansi/awwa c207 (2013b) flange classes, gasket materials, and flange diameters. Lookup flange bolt torque patterns on your phone in seconds. Diameter are based on 30 ksi yield strength. Web it’s also important to avoid deforming the flange faces. Based on the users input, the torque calculator generates a. There are two aspects to consider: 12 bolt flange torque pattern author: Web to calculate the torque required to tighten a bolt: F = bolt load in n. Look up torque specification — use a torque. Web torque values for bolts greater than 1.1/2 in. Web flange joints require proper tightening to avoid leakage. Web these metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Determine bolt size — find the diameter and thread pitch of the bolt. Bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Web flange bolt torque patterns. D = bolt diameter in mm.

Bolt Tightening Sequence and Restrictions Hex Technology

Printable Bolt Torque Chart Printable World Holiday

Bolt Torque Patterns Free Patterns Images and Photos finder

12 Bolt Torque Pattern

Metric Bolt Torque Chart Into Aluminum

FREE Sample Bolt Torque Chart Templates In PDF MS Word, 43 OFF

8 Steps to Properly Installing a Gasket Triangle Fluid Controls Ltd.

Flange Bolt Torque Sequence UIP International

Torque Charts Industrial Bolting and Torque Tools

Torque Charts Industrial Bolting and Torque Tools

9702365 • As 06/14 Torque Poster.

1, 9, 5, 3, 11, 7, 2, 10, 6, 4, 12, 8.

Recommended Torque Values Lubricated Stud Bolts W/0.15 Friction Value.

9/16 12 4912 35 39 46 11599 65 82 92 109.

Related Post: