10 Bolt Torque Pattern

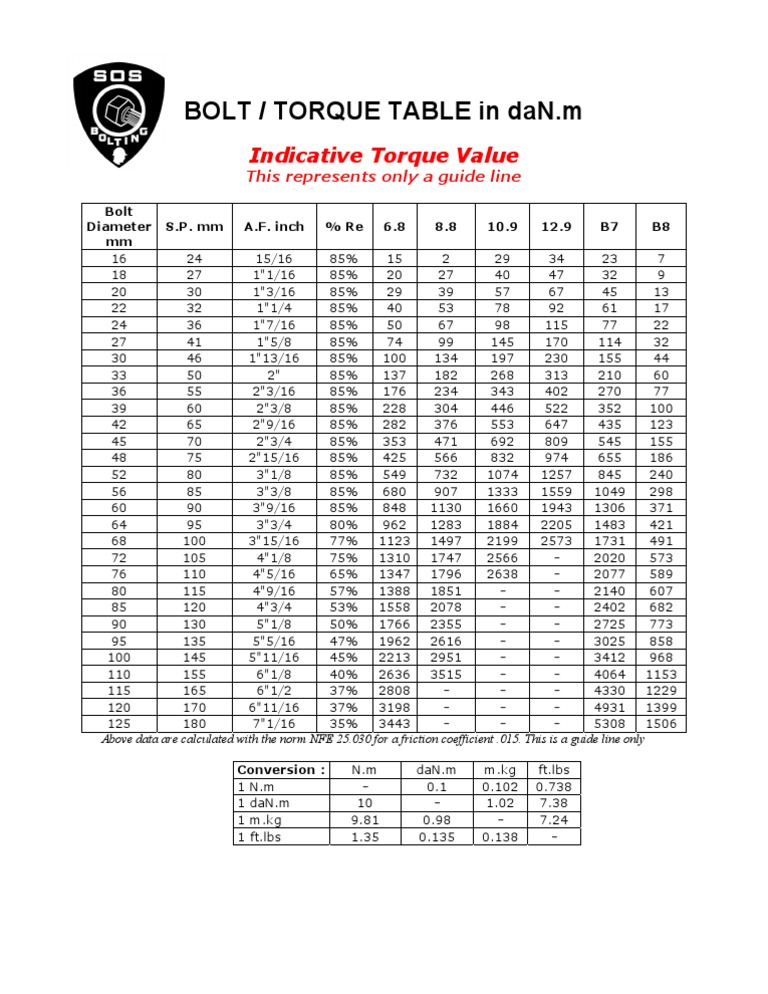

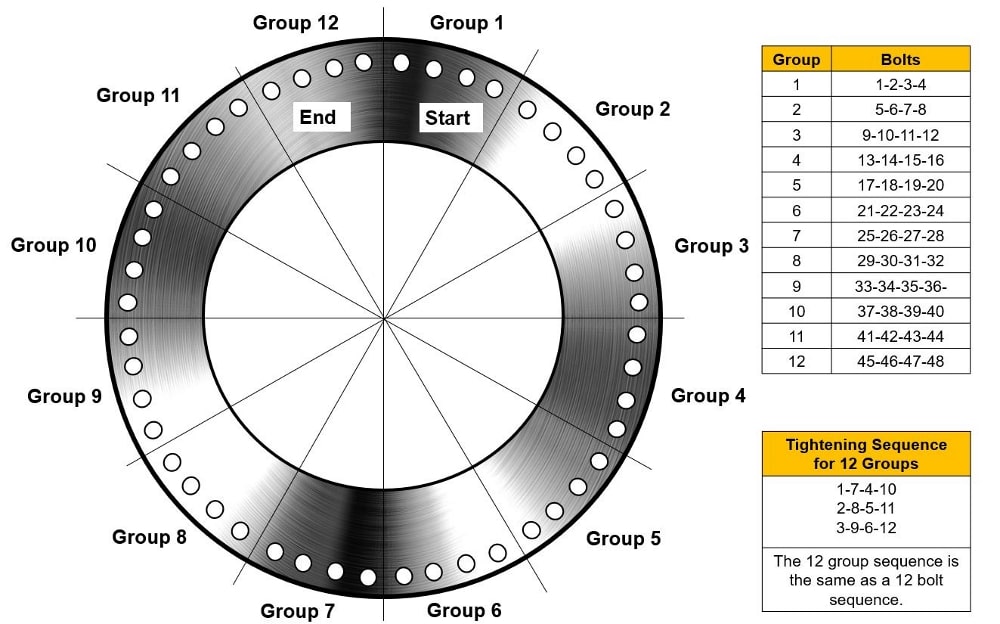

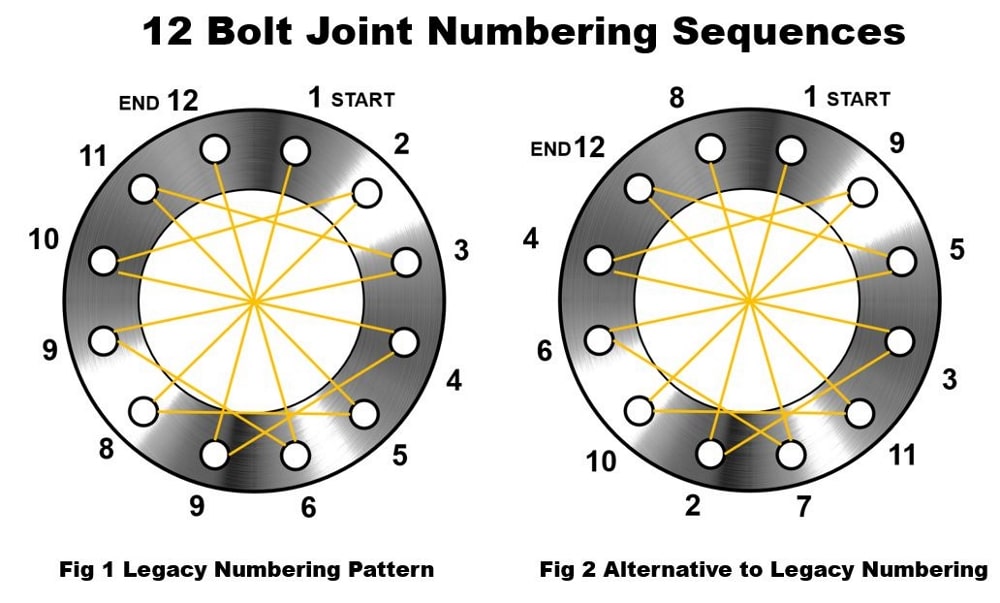

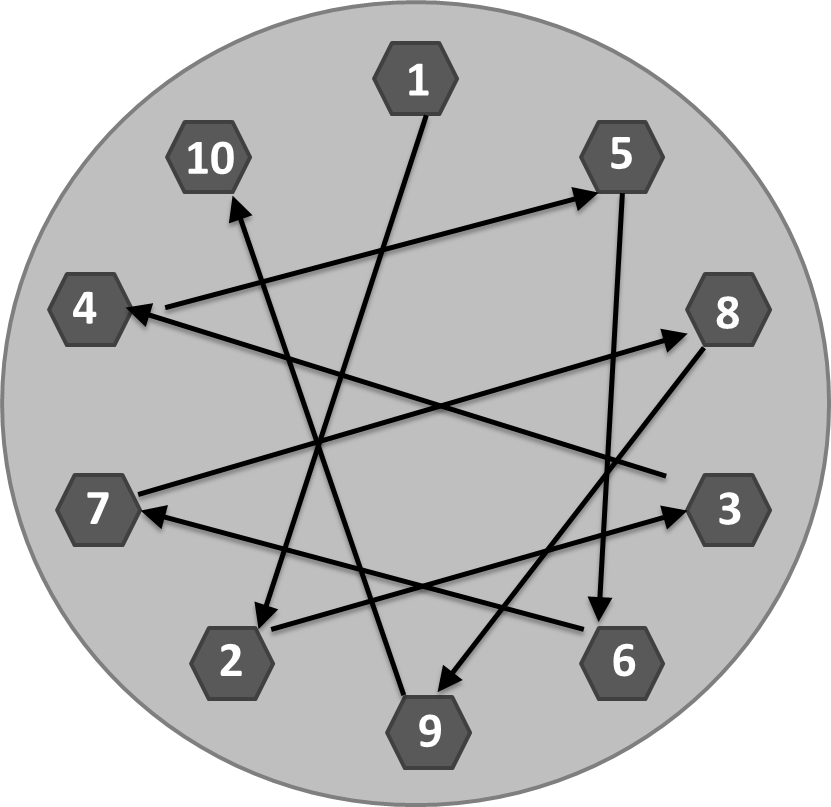

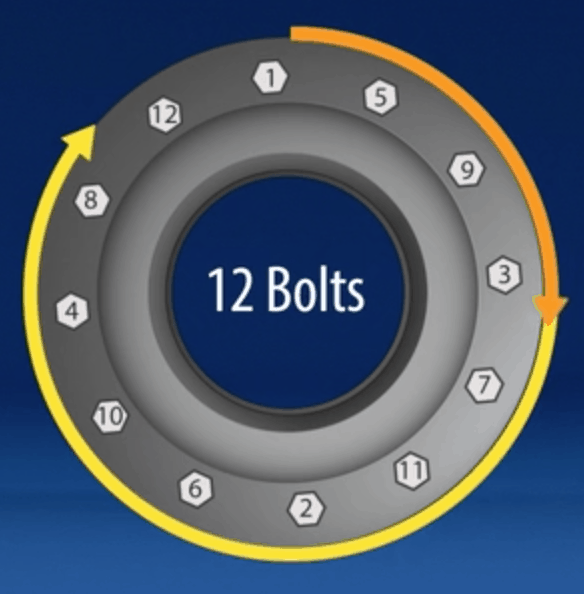

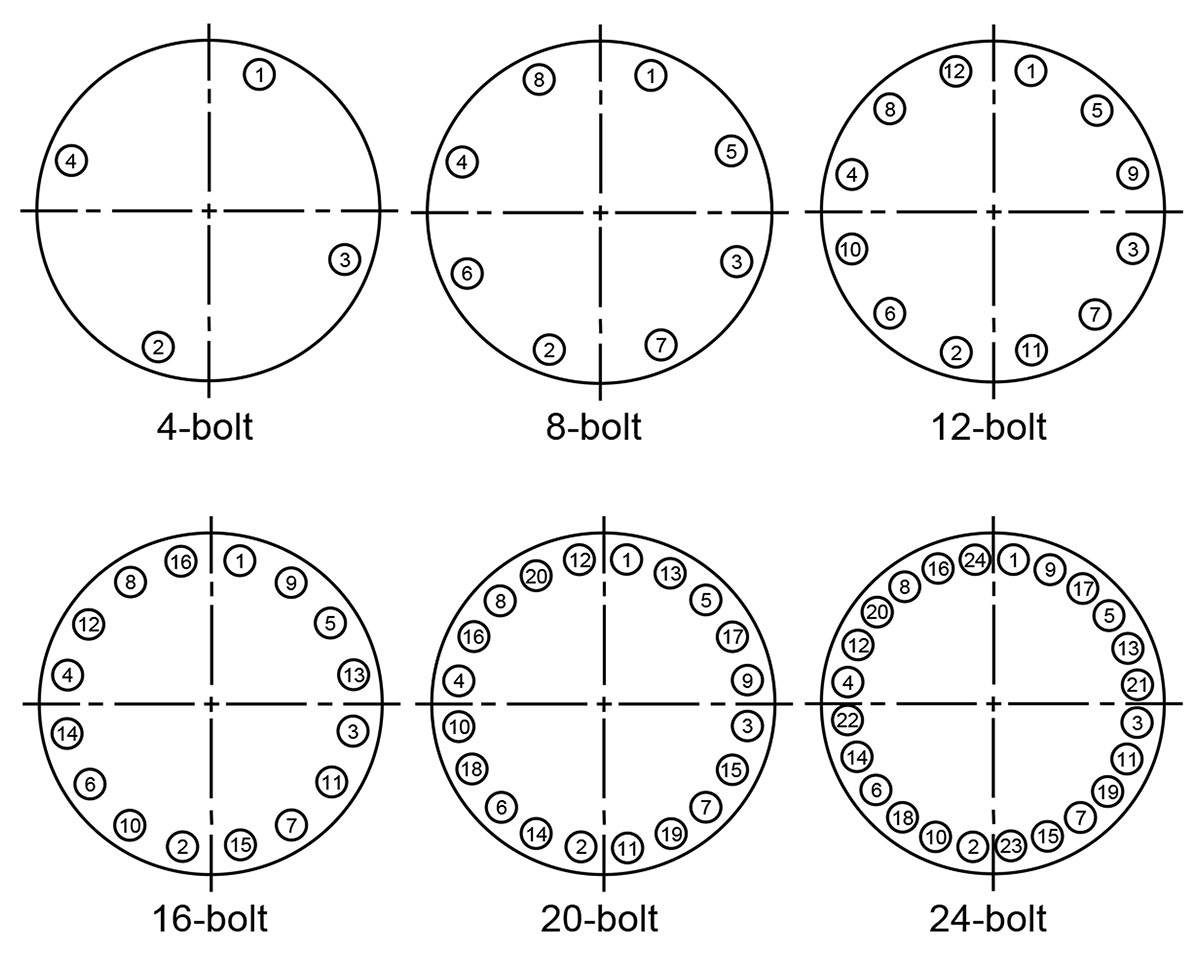

10 Bolt Torque Pattern - Bolt pattern and torque specification. This is achieved because not every bolt goes through the different torque load amounts. Instant flange bolt sizes and torque patterns: This critical step ensures that the gasket stress has Then hand tighten till they are snug against the flanges. Foot/lbs olds / pontiac dropout: If an air wrench is used make. Bolt tightening sequence to follow. Following the pattern described above, insert the bolts and run up the nuts by hand. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. Bolt pattern and torque specification. Alternative assembly pattern #2 quadrant pattern. Continue tightening all fasteners until there is no nut movement in a complete 360 degree pass. Web all data is stored locally on your phone. Web these metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Tighten bolt to specified torque. Instant flange bolt sizes and torque patterns: Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. Repeat with the torque wrench at 60%. The first time around tighten to approximately 1/2 of. Continue tightening all fasteners until there is no nut movement in a complete 360 degree pass. Tighten bolt to specified torque. Backlash is the amount of play the ring gear can move before the pinion moves. Repeat again with the torque wrench at 100%. The bolt’s class indicates its material strength, with higher numbers meaning higher tensile and yield strength. Mark bolt heads in a circular pattern. Web the formula for bolt tightening torque calculation is: Continue tightening all fasteners until there is no nut movement in a complete 360 degree pass. For those who need to download an image (the top graphic is svg) we include a high resolution image of the 20 bolt torque sequence below. (the app. Check that gasket is getting compressed uniformly. Set the torque wrench to 30% of full torque and, using the pattern, tighten each fastener. This critical step ensures that the gasket stress has 9702365 • as 06/14 torque poster. Where k is the torque coefficient, d is the nominal diameter of the bolt, and p is the bolt's clamping force. This is achieved because not every bolt goes through the different torque load amounts. Find a dealer / installer; Shown is the bolt tightening sequences for typical circular flanges. 1, 17, 9, 5, 13, 3, 19, 11, 7, 15, 2, 18, 10, 6, 14, 4, 20, 12, 8, 16. And for the fourth pass, you. If an air wrench is used make. Web differential setup & torque specifications; Repeat with the torque wrench at 60%. Torque pattern for 20 bolt flanges. Find a dealer / installer; Uses the same pattern as the legacy method but allows fewer passes and less overall effort. If an air wrench is used make. These are used to check the backlash of the gears and the thickness of the shims respectively. Start the tightening procedure by lubricating the nuts and bolts. Check that gasket is getting compressed uniformly. The first time around tighten to approximately 1/2 of the final torque, and then repeat the sequence, tightening to the suggested torque limit. Web relaxation of the system (bolts, gasket, and flange) to take place. Then hand tighten till they are snug against the flanges. Alternative assembly pattern #2 quadrant pattern. Torque pattern for 20 bolt flanges. Simpler to follow than the legacy pattern. Tighten bolt to specified torque. And for the fourth pass, you. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. Verify that the lines are broken. This critical step ensures that the gasket stress has Check that gasket is getting compressed uniformly. Web follow along as our employee zach installs a gm 10 bolt rebuild kit from motive gear. The classes are set by the international standards organisation or iso. Bolt tightening sequence to follow. Torque to a maximum of 60% of the final torque. Uses the same pattern as the legacy method but allows fewer passes and less overall effort. Tighten bolt to specified torque. Repeat with the torque wrench at 60%. 60 55 passenger / 55 truck: Do not fully tighten the bolts the first time around as this can tilt the flange out of parallel. Web relaxation of the system (bolts, gasket, and flange) to take place. The first time around tighten to approximately 1/2 of the final torque, and then repeat the sequence, tightening to the suggested torque limit. Alternative assembly pattern #2 quadrant pattern. The table below shows the torque sequence for flanges with 4 to 32 bolts. Backlash is the amount of play the ring gear can move before the pinion moves.

Flange Bolt Torque Sequence UIP International Premium, 53 OFF

Bolt Torque Patterns Free Patterns Images and Photos finder

HEICOLOCK Washers Installation Guidelines

Bolt Tightening Sequence and Restrictions Hex Technology

Printable Bolt Torque Chart

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Torque Charts Industrial Bolting and Torque Tools

Printable Bolt Torque Chart

8 Steps to Properly Installing a Gasket Triangle Fluid Controls Ltd.

Torque Charts Industrial Bolting and Torque Tools

Find A Dealer / Installer;

Following The Pattern Described Above, Insert The Bolts And Run Up The Nuts By Hand.

Web Ultimately, The Ls Head Bolt Torque Specs Are Pretty Difficult To Explain Without A Proper Demonstration.

Web Keep Repeating Until Every Bolt Has Been Tightened.

Related Post: